TM 5-5420-226-20-3

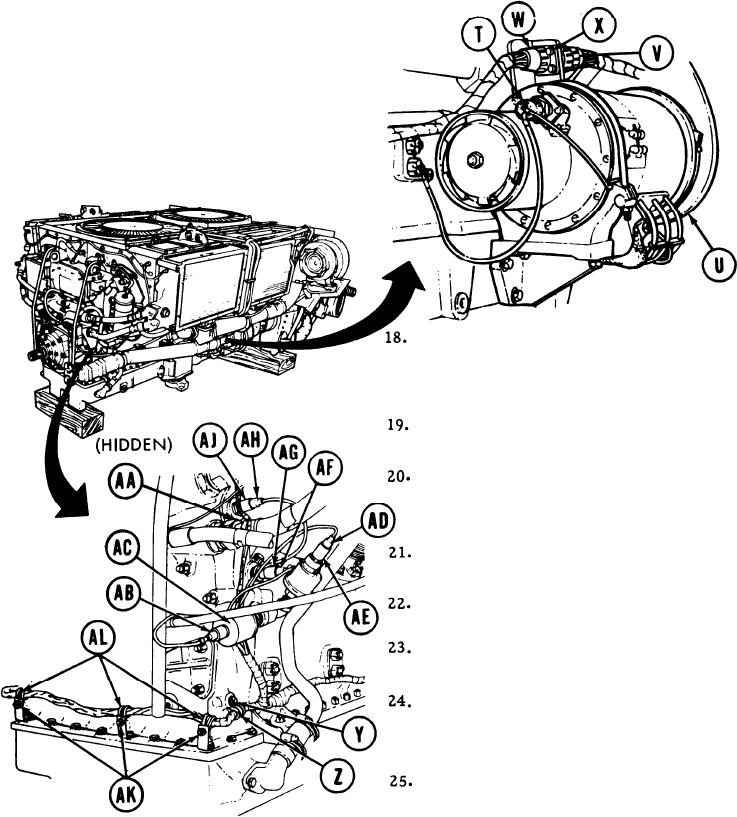

ENGINE WIRING HARNESS REPLACEMENT (Sheet 4 of 12)

Using spanner wrench, disconnect electrical

16.

connector (T) from generator (U).

17. Using spanner wrench, disconnect

electrical connector (V) from

electrical connector (W).

.-

Using cross-tip screwdriver and

adjustable wrench, remove four

screws, lockwashers, and nuts (X)

securing electrical connector (W).

Using 1/2 inch socket, remove screw

and lockwasher (Y).

Remove clamp (Z).

Using 1/2 inch socket with extension,

remove nut (AA) securing clamp (hidden).

Remove clamp.

Disconnect electrical connector (AB)

from engine oil pressure switch (AC).

Disconnect electrical connector (AD)

from engine high oil pressure trans-

mitter (AE).

Disconnect electrical connector (AF)

from engine oil high temperature

thermostatic switch (AG).

26. Disconnect electrical connector (AH) from engine oil temperature transmitter (AJ).

27. Using 7/16 inch socket and wrench, remove three screws, lockwashers and nuts (AK).

28. Remove three clamps (AL).

TA168940

Go on to Sheet 5

10-289