TM 5-5420-226-20-3

BRAKE PRESSURE GAGE, TUBE ASSEMBLY, REDUCER, AND GASKET REPLACEMENT

(Sheet 4 of 7)

CLEANING AND INSPECTION:

Cleaning agent specified is flammable. Use only in well ventilated areas. Keep away from

flames, sparks, or heat. Do not smoke while using. Prevent contact with eyes, mouth, and/or

skin. Wear rubber gloves when performing cleaning procedures.

Using rags and dry cleaning solvent,

1.

clean all parts inside and out.

2.

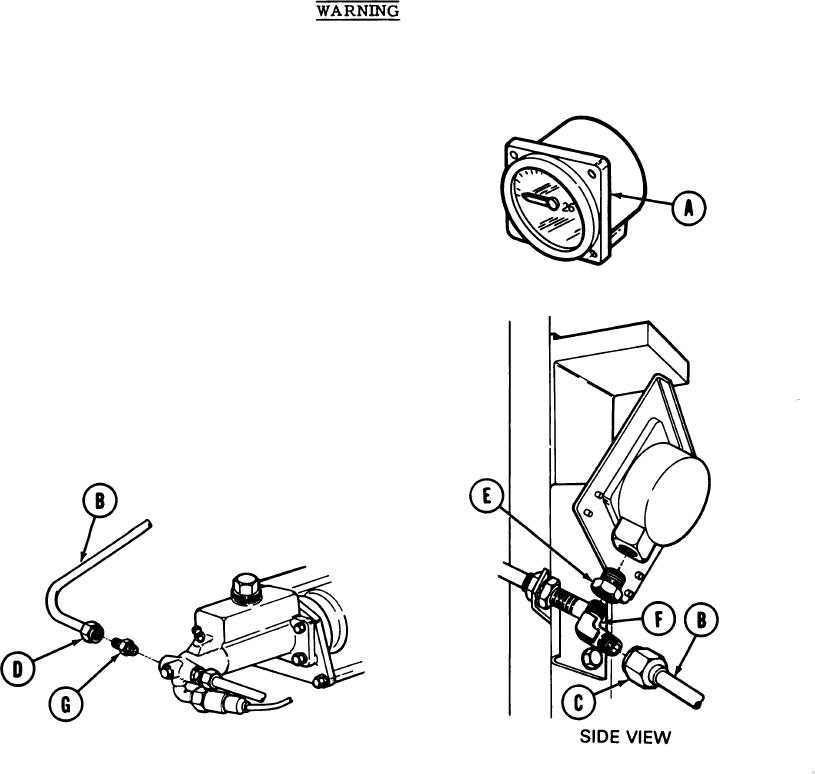

Inspect gage (A) for cracked or broken

glass. Replace if unserviceable.

3.

Inspect brake tube assembly (B) and

tube connecting nuts (C) and (D) for

worn threads, holes, and cracks. Replace

if unserviceable.

Inspect nut (E) and elbow (F) for worn

4.

threads and cracks. Replace if unservice-

able.

5.

Inspect reducers (G) for worn threads

or cracks. Replace if unserviceable.

Go on to Sheet 5

TA169166