TM 5-5420-226-20-3

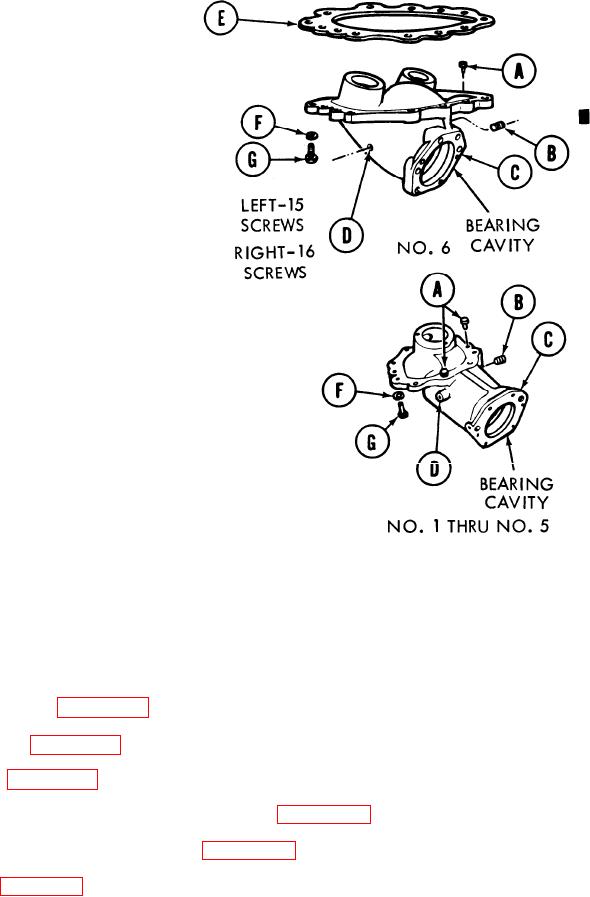

ROADWHEEL SUPPORT HOUSING ASSEMBLY REPAIR AND REPLACEMENT (Sheet 2 of 2)

REPAIR:

1.

Using hammer, tap two straight pins (A)

to loosen them. Using pliers, pull pins (A) out.

Using adjustable wrench, remove plug (B)

2.

from housing (C).

3. Inspect housing (C). Replace if necessary.

4. Coat support housing bearing cavity

with grease.

5. Using adjustable wrench, install plug (B).

6.

Inspect grease fitting (D). Replace if necessary.

INSTALLATION:

1. Using hammer and drift punch, drive two pins (A) into place.

2. Apply sealing compound to mating surfaces of hull and housing (C).

3. Lift housing (C) and gasket (E) and position to mounting place.

Aline holes in gasket (E) and housing (C) with holes in hull mounting place.

4.

5. Install lockwashers (F) and screws (G) securing housing (C) to hull.

6. Using socket, alternately tighten screws (G).

7.

Using torque wrench, socket, and extension bar, tighten screws (G) to 450 to 475 lb-ft

(610-644 Nm).

8. Install torsion bar anchor (page 14-34).

9. Install roadwheel arm (page 14-17).

10. Install torsion bars (page 14-29).

11. Connect bottom of shock absorbers (where necessary) (page 14-92).

12. Connect rear of adjusting link (if necessary) (page 14-78).

13. Install roadwheels (page 14-5).

End of Task

14-25

Change 3