TM 5-5420-226-20-3

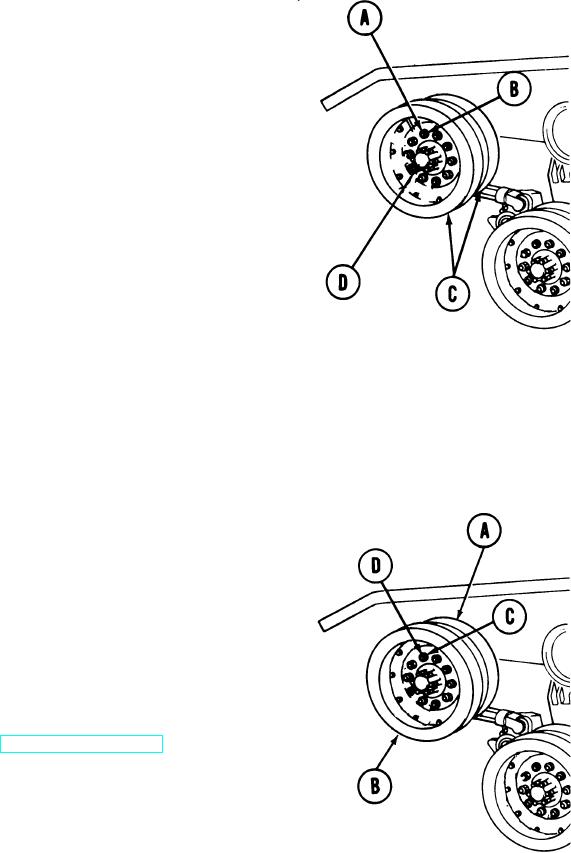

COMPENSATING IDLER WHEEL REPLACEMENT (Sheet 3 of 3)

1.

Using 1-1/2 inch socket with extension

and hinged handle, remove 10 nuts (A)

and flat washers (B) securing roadwheel

(C) to wheel hub (D).

2.

Using second technician for help, pull one

roadwheel - then the other, off mounting

studs.

CLEANING AND INSPECTION:

Inspect and clean mounting hub surface

with wire brush and rag prior to mounting

roadwheels.

INSTALLATION:

NOTE

Do not damage hub mounting studs when installing rotad-

wheels.

Position inside compensating idler wheel (A).

1.

Position outside compensating idler wheel (B).

2.

3.

Install 10 flat washers (C) and nuts (D).

4.

Using 1-1/2 inch socket wrench with

extension and torque wrench, tighten

nuts (D) to 400-500 lb-ft (542 -678 Nm).

Reconnect track (TM 5-5420-226-10).

5.

End of Task

TA169316