`I'M 5-5420-228-24

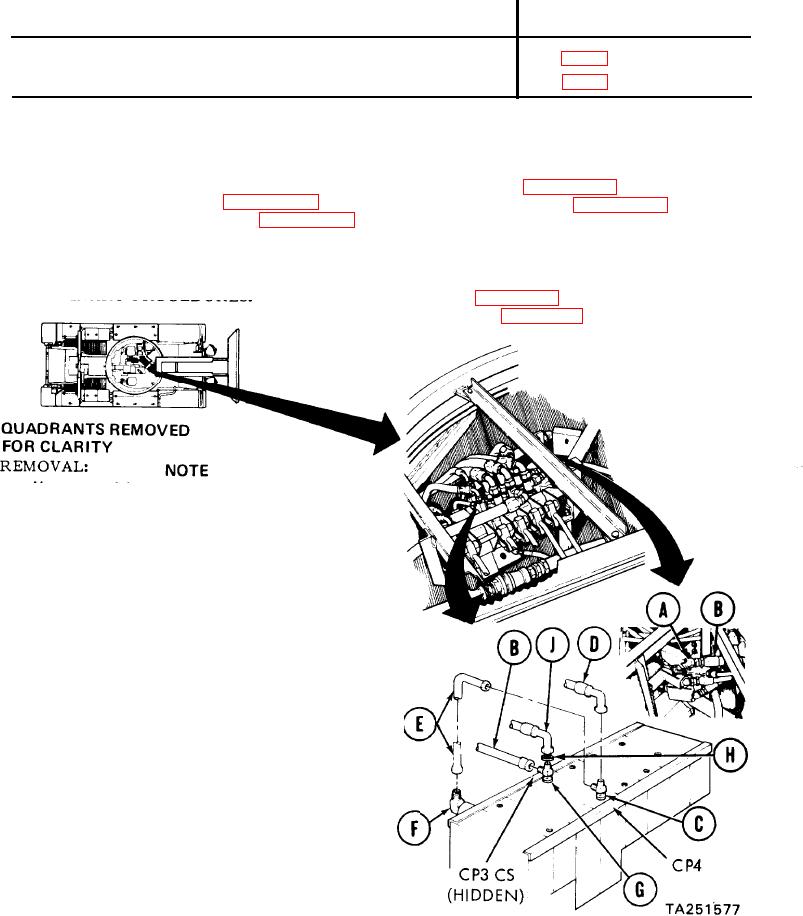

LOCKING CYLINDER HOSE ASSEMBLIES (EA1, CP3, CP4 and CS) AND HYDRAULICS

REPLACEMENT (Sheet 1 of 4)

PROCEDURE INDEX

PROCEDURE

PAGE

Removal

Installation

TOOLS: 12 in. adjustable wrench (2)

15/16 in. open end wrench

8 in. pipe wrench

1-1/4 in. open end wrench

11/16 in. open end wrench

7/8 in. open end wrench

SUPPLIES:

Drip pans (suitable containers)

Pencil (Item 22, Appendix D)

Rags (Item 12, Appendix D)

Masking tape (Item 18, Appendix D)

Pipe tape (Item 19, Appendix D)

Preformed packing (4 required)

REFERENCE:

LO 5-5420-202-12

PRELIMINARY PROCEDURES:

Remove front quadrant (page 3-45)

Relieve hydraulic pressure (page 3-71)

Use rags and drip pans to catch excess hydrau-

Iic fluid. Use masking tape tags to tag lines for

installation.

Using adjustable wrench on elbow (A), use

1.

1-1/4 inch wrench to remove hose assembly

"CS" (B).

Using adjustable wrench on tee (C), use

2.

adjustable wrench to disconnect hose

assemblies "CP4" (D) and "EA1" (E).

3.

Using adjustable wrench on elbow (F), use

15/16 inch wrench to remove hose assembly

"EAl" (E).

4.

Using adjustable wrench on tee (G), use 1-1/4

inch wrench to remove hose assembly "CS" (B).

5.

Using 1-1/4 inch wrench on nut (H), use

11/16 inch wrench to remove hose assembly

"CP3" (J).

G O on to Sheet 2