TM 5-5420-280-23&P

0015 00

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (Contd)

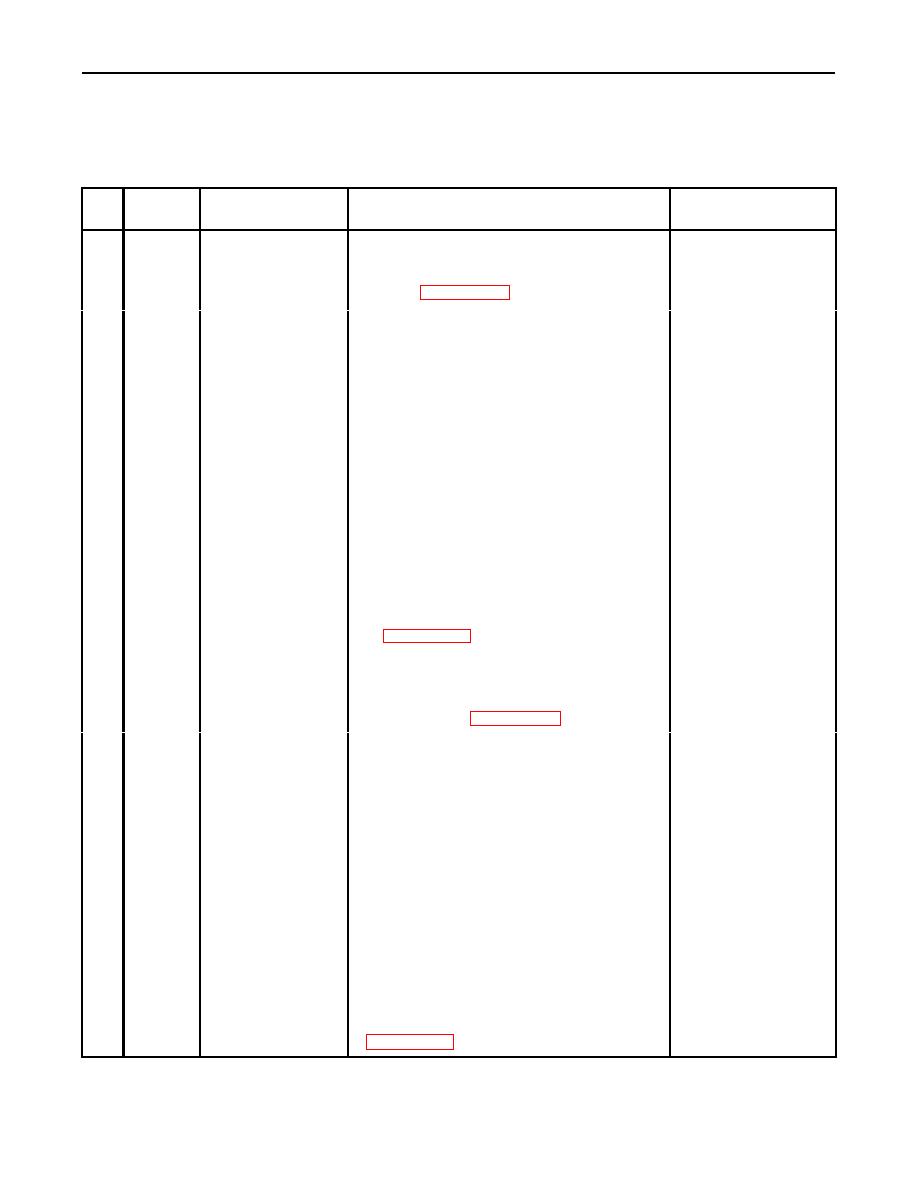

Table 1. Preventive Maintenance Checks and Services for Pallet (Contd).

ITEM

ITEM TO

EQUIPMENT NOT

INTERVAL

PROCEDURE

NO.

CHECK/ SERVICE

READY/AVAILABLE IF:

13

Annual

Supporting cylinder

a. Check for damage, cracks, or missing pin.

Supporting cylinder

bottom plate (1)

bottom plate is

b. Repair or replace damaged or missing pins.

damaged or pin is

Refer to WP 0038 00.

missing.

14

Annual

Supporting cylinder

a. Check for damaged or missing retaining

a. Retaining pins are

(2), winch (11)

pins.

missing or

ratchet clutch (10),

damaged.

strap (7), retaining

pins (9), and

b. Check for damaged or missing hand winch

b. Strap or strap ends

support rollers (8)

strap or strap end.

are damaged or

missing.

c. Check winch strap and ratchet clutch

c. Strap is binding or

operation for binding or slippage using BII

ratchet clutch

ratchet.

slipping or not

operational.

d. Check hydraulic hoses, fittings, and lines

d. Lines, hoses, or

fittings are

for damage or leaks.

damaged, or Class

III leak is noted.

e. Repair or replace missing hardware,

damaged strap, or hoses and fittings. Refer

to WP 0039 00.

f. Check check for damaged or missing rollers.

g. Repair or replace damaged or missing

rollers. Refer to WP 0044 00.

15

Annual

Supporting

a. Check supporting wheel and retaining

wheel (3), tire (6),

bracket for damage or missing hardware.

hydraulic

cylinders (4), and

b. Check tire for cuts, cracks, or deflation.

Add air as necessary, fill to 100 psi

retaining

(690 kPa).

bracket (5)

c. Check hydraulic cylinders for loose or

missing hardware.

d. Any Class III leak is

d. Check hydraulic cylinders, lines, and

noted or faulty

fittings for leaks, or if tubing is kinked or

cylinders prevent

damaged.

transload or

transport of pallet

on ground.

e. Repair or replace missing hardware,

cylinders, tires, lines, and fittings. Refer to

0015 00-10