TM 5-5420-280-23&P

0111 00

ENGINE FUEL INJECTOR REPLACEMENT (Contd)

CAUTION

Cap or plug all hoses, tubes, connections, and openings immediately

after disconnection to prevent contamination. Remove caps or

plugs prior to installation. Failure to do so may result in damage to

equipment.

NOTE

Removal and installation of each fuel injector is performed the

same way. Cylinder number two is shown.

REMOVAL

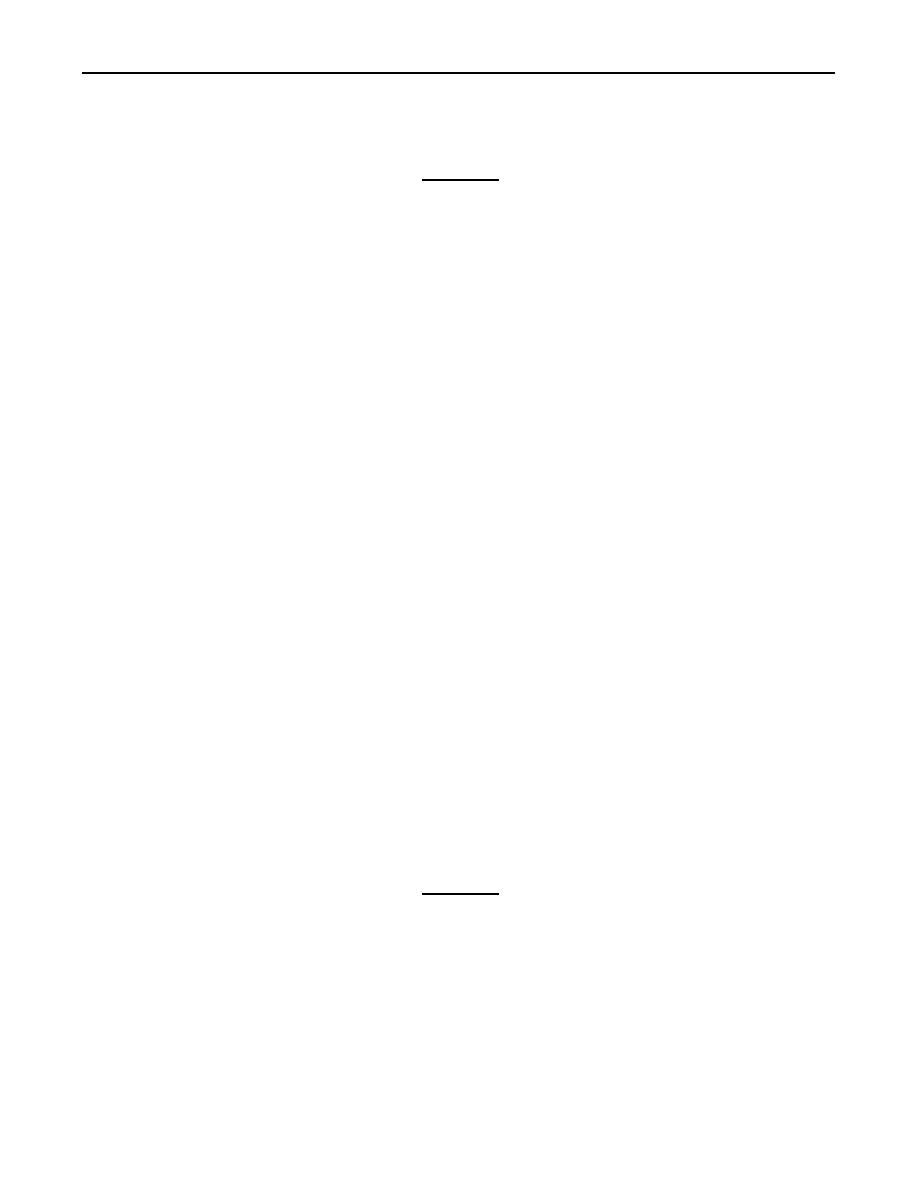

1.

Loosen nuts (1), (4), (15), and (20) and remove fuel pressure pipe assemblies (2) and (3)

from fuel injectors (9) and (19) and injection pump fitting (13) and (14).

2.

Remove fuel return hose (16) from hose nipple (17).

3.

Remove fluid passage bolt (21), gasket (18), hose nipple (17), and gasket (18) from fuel injector (9).

Discard gaskets (18).

4.

Remove nut (5), spring washer (6), spacer (7), and fuel injector clamp (8) from stud (11). Discard

spring washer (6)

NOTE

Gasket may stay in bore of cylinder head. Check bore if gasket is

not on the end of fuel injector.

5.

Remove fuel injector (9) and gasket (10) from engine (12). Discard gasket (10).

INSTALLATION

NOTE

Make sure that soft, graphite-coated surface of gasket is facing fuel

injector.

Make sure tapered side of spacer is toward injector clamp and that

tapered side of injector clamp is facing up.

1.

Install new gasket (10) on fuel injector (9) and install fuel injector (9) in cylinder number two with

fuel injector clamp (8), spacer (7), new spring washer (6), and nut (5). Tighten nut (5) to 17 ft-lb

(23 Nm).

2.

Install new gasket (18), hose nipple (17), new gasket (18), and fluid passage bolt (21) on fuel

injector (9).

3.

Install fuel return hose (16) on hose nipple (17).

4.

Install fuel pressure pipe assemblies (2) and (3) on fuel injectors (9) and (19) and injection pump

fittings (13) and (14) and tighten nuts (1), (4), (15), and (20).

CAUTION

Never use starting fluid (ether) to assist starting LPU. Failure to

comply will result in damage to engine.

5.

If necessary, operate fuel priming pump. Refer to TM 5-5420-280-10.

6.

Run engine briefly to check for leaks. Refer to TM 5-5420-280-10.

0111 00-2