TM 5-1940-322-24

0011 00

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS) (Contd)

Table 1. Preventive Maintenance Checks and Services (Contd).

ITEM

ITEM TO

NOT FULLY

INTERVAL

PROCEDURE

NO.

CHECK/SERVICE

MISSION CAPABLE IF:

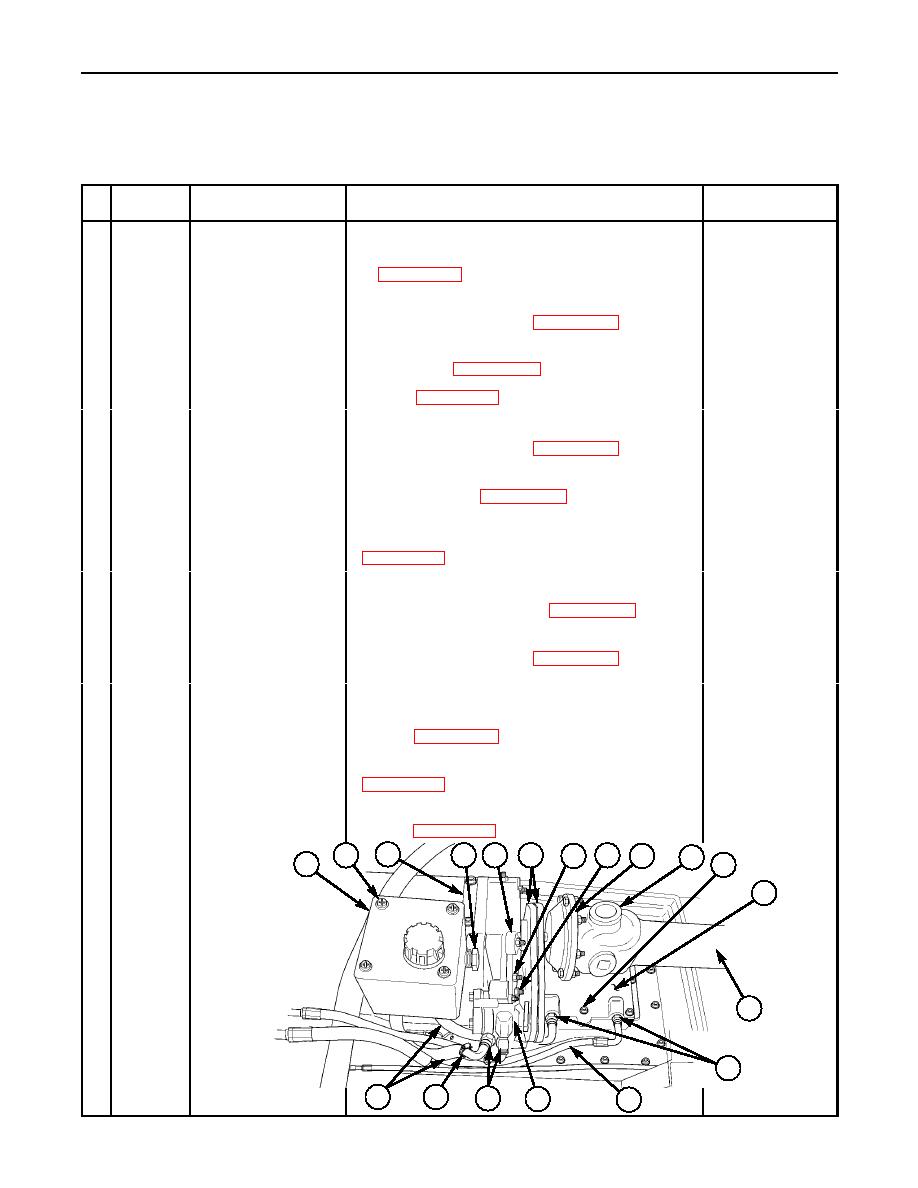

14.

Quarterly Port and starboard

a. Inspect for missing, loose, or damaged reservoir,

a. Missing loose, or

screws, nuts, or mounting hardware. Repair or

scoop control hydraulic

damaged.

replace damaged, loose, or missing hardware. Refer

reservoirs (1), site

to WP 0131 00.

glass (4), hoses (19),

fittings (17), screws (2), b. Inspect hydraulic hoses and fittings for leaks or

b. Any Class III

clamps (18), and

leak.

damage. Repair or replace damaged, loose, or

mounting brackets (3).

missing hardware. Refer to WP 0131 00.

c. Inspect reservoir oil level on site glass; if necessary

fill reservoir with oil until oil is at center of site

glass. Refer to WP 0012 00. Repair or replace

damaged, loose, or missing hardware.

Refer to WP 0131 00.

15.

Quarterly Port and starboard

a. Inspect hydraulic pump, hoses, and fittings for leaks a. Any Class III

or damage. Repair or replace damaged, loose, or

scoop hydraulic

leak or damage.

missing hardware. Refer to WP 0132 00.

pumps (16), drive

belts (6), hoses (19),

b. Inspect pump drive belt and adjust as required.

b. Missing or

fittings (17), mounting

Repair or replace damaged, loose, or missing

damaged.

brackets (5),

hardware. Refer to WP 0132 00.

screws (8), and

c. Missing or

c. Inspect for missing, loose, or damaged mounting

nuts (7).

brackets and mounting hardware. Repair or replace

damaged.

damaged, loose, or missing hardware. Refer to

16.

Quarterly Port and starboard

a. Inspect hydraulic hoses, fittings, and oil cooler for

a. Any Class III

leaks or damage. Repair or replace damaged, loose,

hydrojet oil cooler

leak or damage.

or missing hardware. Refer to WP 0130 00.

housings (12),

hydraulic hoses (15),

b. Missing, loose, or

b. Inspect for missing, loose, or damaged mounting

fittings (14),

damaged.

hardware. Repair or replace damaged, loose, or

screws (11), and

missing hardware. Refer to WP 0130 00.

mounting hardware.

17.

Quarterly Port and starboard

a. Inspect for missing, loose, or worn binding or

a. Missing, loose, or

damaged driveshaft flange or driveshaft. Repair or

hydrojet driveshaft

damaged.

replace damaged, loose, or missing hardware.

flanges (9),

Refer to WP 0128 00.

driveshafts (13),

U-joints (10), and

b. Inspect U-joints. Repair or replace driveshaft if

mounting hardware.

damaged, loose, or missing hardware. Refer to

c. Out-of-balance

c. Observe operating shaft for signs of imbalance.

driveshaft.

Tighten hardware or replace driveshaft as necessary.

Refer to WP 0128 00.

3

2

4

5

6

8

7

9

10 11

1

12

~

13

14

19

18

17

16

15

0011 00-10