TM 5-1940-322-24

0157 00

FLYWHEEL, FLYWHEEL HOUSING, AND CRANKSHAFT REAR SEAL MAINTENANCE (Contd)

MEASUREMENT

1.

Install flywheel housing (2) on cylinder block (3) with eight screws (1).

2.

Install two T-handles (4) on flywheel (5).

3.

Position sling and lifting device around T-handles (4) to support flywheel (5) during lifting operations.

4.

Install two guide pins (7) in flywheel housing (2) 180 apart.

5.

Using sling and lifting device, install flywheel (5) on guide pins (7) and flywheel housing (2).

6.

Install six screws (8) in vacant holes in flywheel (5). Do not tighten screws (8).

7.

Remove two guide pins (7) from flywheel (5) and flywheel housing (2), and install two remaining

screws (8) in flywheel (5) and flywheel housing (2). Tighten all screws (8) to 101 lb-ft (137 Nm) in star

pattern.

8.

Using gear barring tool, rotate crankshaft (6) one complete revolution.

9.

Using dial indicator and dial indicator adapter, measure flywheel bore (9) and flywheel face

surface (10) run-out. Total Indicator Reading (TIR) must not exceed 0.0050 in. (0.127 mm).

10.

If TIR is greater than specifications, remove flywheel (5) as shown in removal procedure and inspect

for dirt, damage, or out-of-roundness.

11.

Inspect crankshaft (6) for dirt or damage.

12.

Perform steps 4 through 11 to re-install flywheel (5) and re-inspect bore run-out. Replace flywheel (5)

if bore run-out does not meet specifications.

13.

Install contact tip of indicator (11) against flywheel face surface (10), as close to outside diameter as

possible, to inspect face run-out.

NOTE

Push the flywheel forward to remove the crankshaft end clearance.

Adjust the dial on the indicator until the needle points to zero.

14.

Using gear barring tool, rotate crankshaft (6) one complete revolution. Measure flywheel (5) run-out at

four equal points on flywheel (5).

15.

Using dial indicator, measure flywheel (5) run-out. Refer to Table 1, Flywheel Radius and Flywheel

Face Limits.

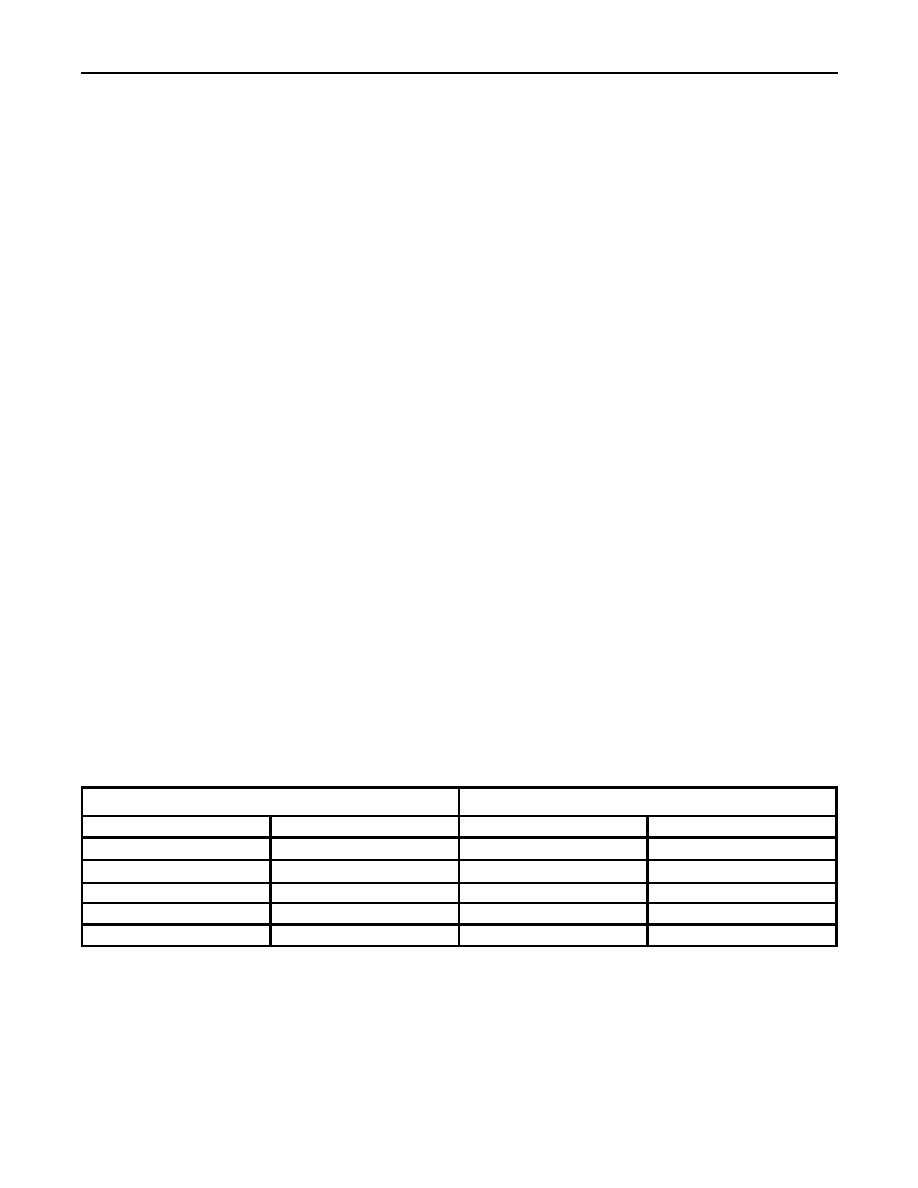

Table 1. Flywheel Radius and Flywheel Face Limits.

Flywheel Radius

Flywheel Face

in

mm

in

mm

8

203

0.008

0.203

10

254

0.010

0.254

12

305

0.012

0.305

14

356

0.014

0.356

16

406

0.016

0.406

16.

If flywheel (5) face run-out is not within specifications, remove flywheel as noted in flywheel removal

procedure and check for burrs, nicks, and foreign material between flywheel mounting surface and

crankshaft (6) flange.

0157 00-6