TM 5-5420-203-14

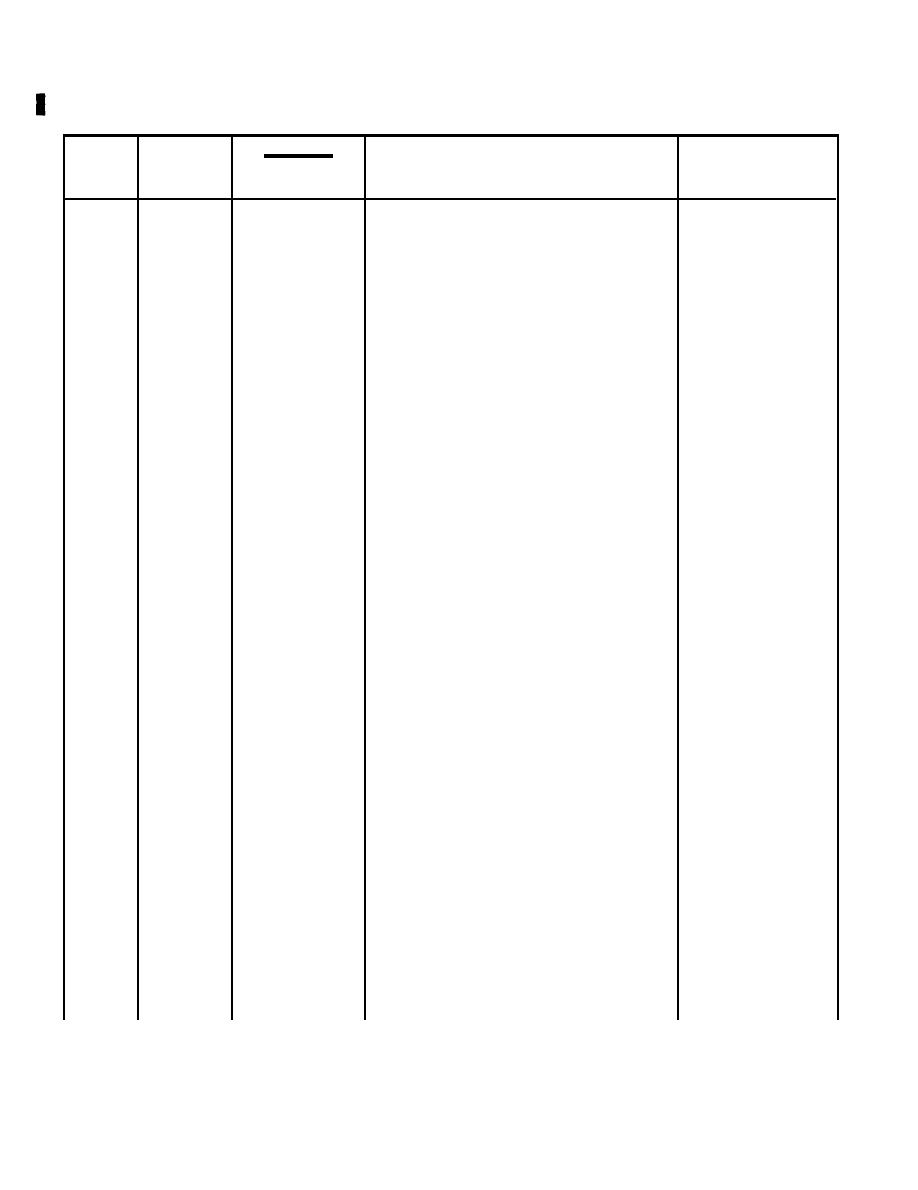

Table 2-2. Preventive Maintenance Checks and Services (PMCS)

Location

Interval

Item to

Item

Not Mission

(B, D, A,

Procedure

Check/Service

Capable if:

No.

W, M)

Tie Rod

Check for missing, loose, or damaged tie

1

BEFORE

Assemblies

rods, tie rod spacer, tie rod nuts/

washers, and housing. Replace any

missing or damaged parts (tie rod is a

non-structural member).

2

BEFORE

Deck

Inspect for missing, cracked, deformed,

One or more deck

or split decking/curbing. Replace as

plates in a row

necessary (decking and curbing are non-

Curbing

missing for wheeled

structural members).

vehicles; three or

more in a row for

tracked vehicles.

Class III leak

Hydraulic

3

Inspect for any hydraulic fluid leaks

BEFORE

Fluid Leaks

exists.

(hydraulic components are non-structural

members)

4***

Rivets, either

One or more CSK

BEFORE

Inspect for missing, loose, broken heads

pin-rivet or hot-

vertical rivets

and collars (in the case of pin-rivets),

rivet - Button

missing or loose in

also any evidence of corrosion (white

the hinge,

Head (BH) or

dust or powder around the hot rivet

head). Also check the ground where a

connector area, or

Countersunk

spliced area in

bridge has been stored for any rivet

(CSK)

ramp. Two or

heads that may have fallen off due to

more BH

corrosion. Report this immediately

horizontal rivets in

through channels. (Rivets/pin-rivets are

considered secondary structural members

top or bottom and

except where they exist in the hinge,

any rivet heads that

connector areas, spliced areas, or at

had fallen off from

either the hinge

locations along the bottom cord where

they connect cross bracing. Rivets in

connector, or

these areas are considered of primary

spliced area of

concern.

AVLB.

2-4 Change 2