TM 5-5420-278-24&P

0069 00

1

RAMP BAY AND INTERIOR BAY TRUNNION REPAIR (Contd)

WARNING

If trunnion is bent or severely worn, it must be completely

replaced. Failure to comply may result in injury to personnel.

NOTE

Build-up welding on trunnion is performed if wear does not exceed

1.181 in. (30 mm). The abrasion or wear may display a variety of

inclinations or crack-like features.

IRB bays are made from corus aluminum ABKANTGUETE

6061-T651 749572.

PREPARATION

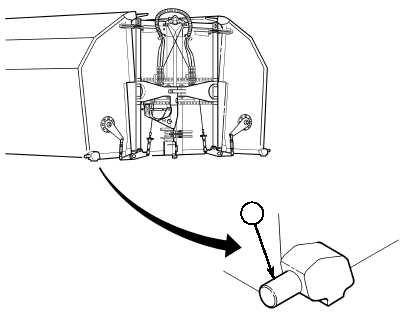

1.

Grind off to beyond ends of cracks on trunnion (1).

2.

Clean welding area with a stainless steel wire brush.

WELDING

NOTE

If temperature is below 59°F (15°C), pre-heat welding area to a

maximum of 302°F (150°C) before welding.

1.

Apply circular welding beads (refer to TC 9-237) from inside towards the outside and position

welding beads closely. Depending upon the required build-up thickness, several circular welding

beads must be applied.

2.

After welding trunnion (1), work diameter and length of trunnion (1) to dimensions provided in

illustrations. Chamfer end of trunnion (1).

3.

Clean, treat, and paint area in accordance with MIL-T-704 TYPE B.

NOTE

Perform steps 4 and 5 on ramp bay trunnions equipped with wear

caps where drilling and tapping a new mounting hole is required.

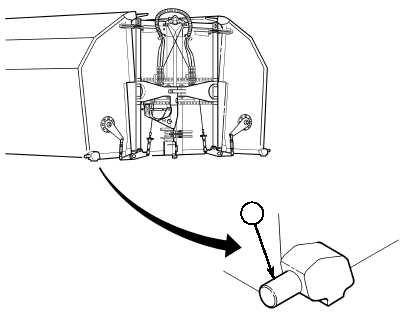

4.

Mark, drill, and tap a M-12 x 25 threaded hole in center of trunnion (1). Install new threaded

insert (2) (refer to WP 0058 00).

5.

Install wear cap (WP 0055 00) (ramp bay only).

6.

Install ramp bay or interior bay on transporter (TM 5-5420-278-10).