TM 5-5420-280-10

0043 00

Preventive Maintenance Checks and Services (PMCS) for Pallet (Contd).

NOT FULLY

ITEM

ITEM TO

MISSION

INTERVAL

PROCEDURE

NO.

CHECK/SERVICE

CAPABLE IF:

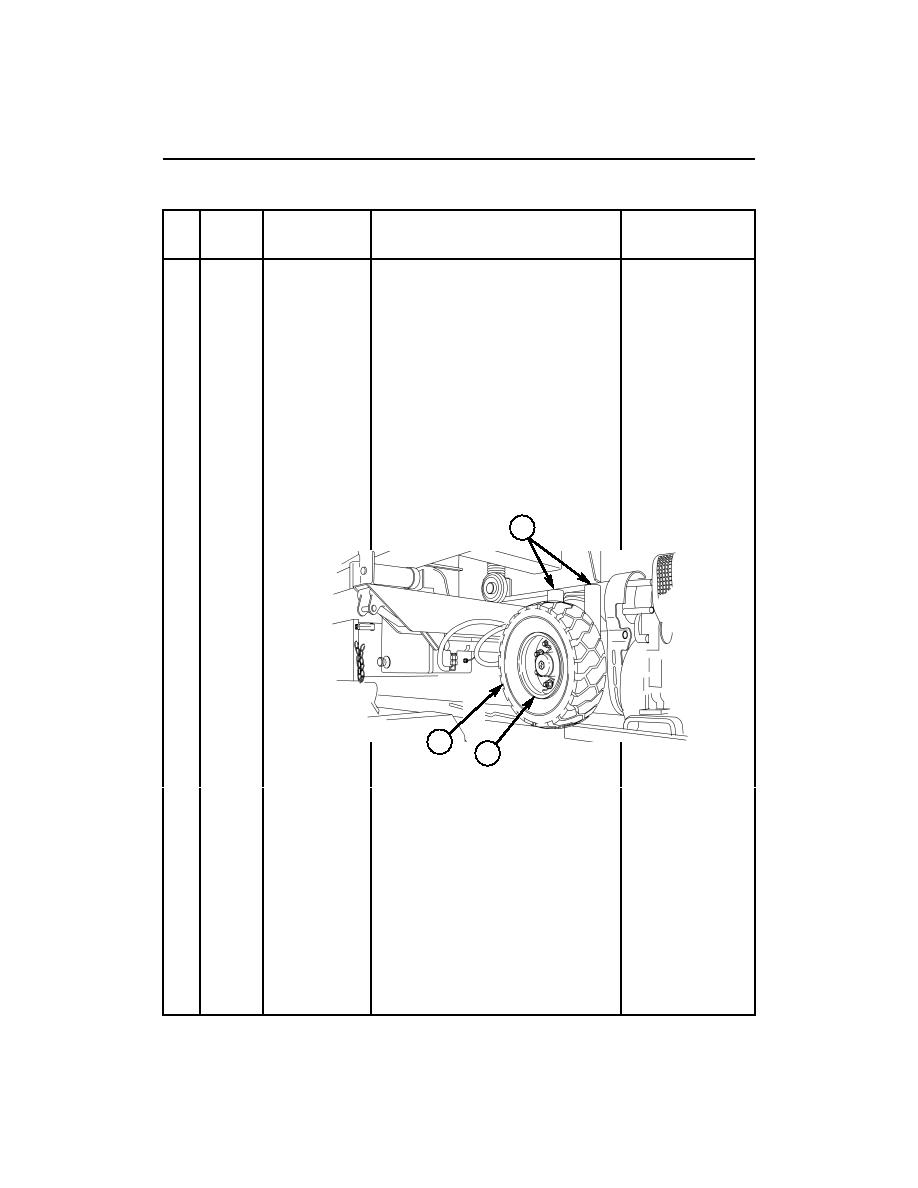

29

Before

Supporting

a. Check supporting wheel and retaining

wheel (2),

bracket for damage or missing hardware.

tire (3), and

Spin wheel to ensure it rotates freely.

hydraulic

cylinders (1)

b. Check tire for cuts, cracks, or

deflation. Check tire pressure and add

air as necessary; fill to 100 psi

(690 kPa).

c. Check hydraulic cylinders for loose or

missing hardware.

d. Any Class III leak

d. Check hydraulic cylinders, lines, and

is noted or faulty

fittings for damage or leaks.

cylinders prevent

transload or

transport of pallet

1

on ground.

3

2

30

Before

LPU engine oil

a. Check oil level before starting engine; a. Oil level is below

level (8), air

level must be visible between maximum minimum.

cleaner (6),

and minimum marks on dipstick.

muffler and

b. Check air cleaner for damage, loose

b. Air cleaner is

elbow (4), fuel

or missing hardware, or obstructions.

damaged or

tank level (7),

obstructed.

and hoses (5)

c. Fuel tank leaks.

damage or loose or missing hardware.

d. Check site tube for full fuel level, and d. Any Class III

check tank for damage, loose or missing leak is noted.

hardware, or leakage.

e. Check hoses for damage or leakage.

0043 00-16