TM 5-5420-280-10

0043 00

Preventive Maintenance Checks and Services (PMCS) for Pallet (Contd).

NOT FULLY

ITEM

ITEM TO

MISSION

INTERVAL

PROCEDURE

NO.

CHECK/SERVICE

CAPABLE IF:

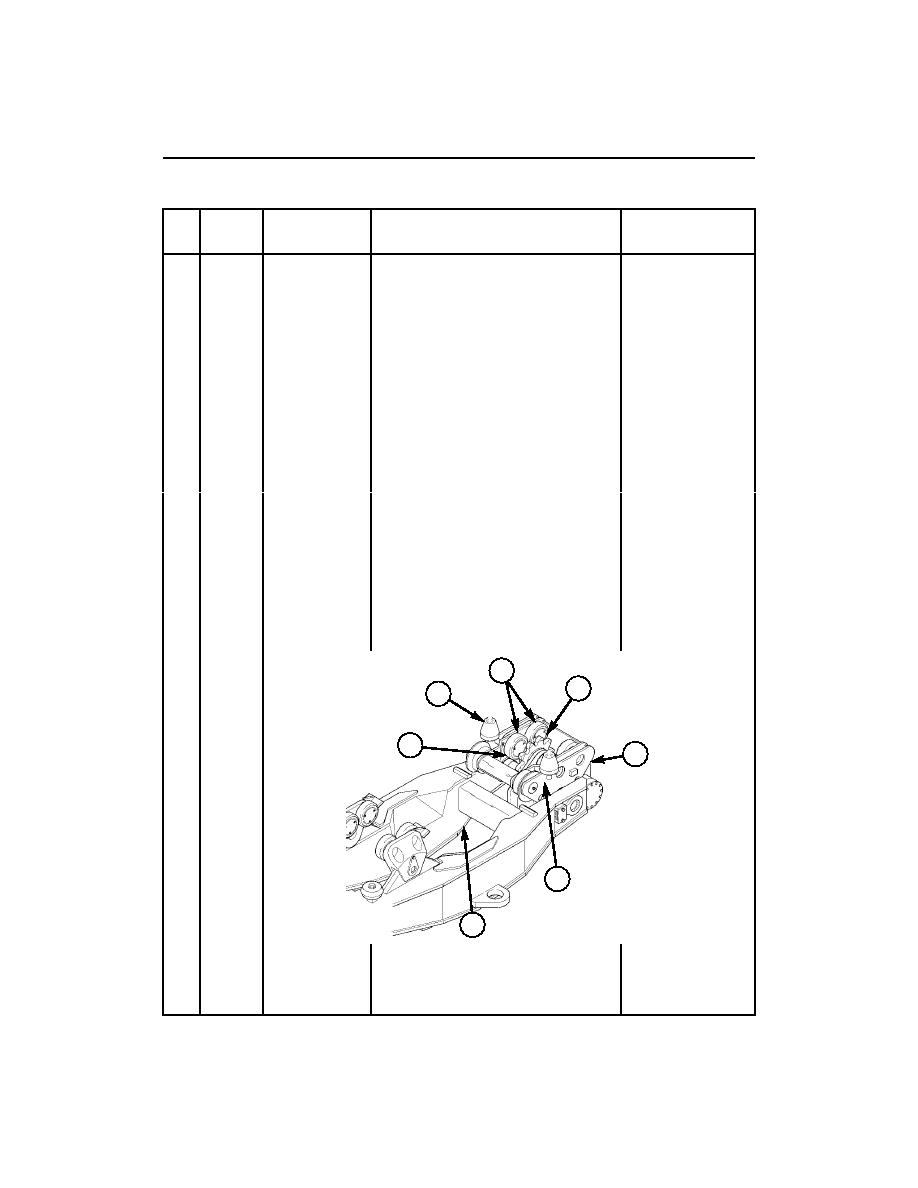

51

During

Roller track

a. Check roller track frame for cracks or a. Any cracks or

frame (6),

damage.

damage.

rollers (3), and

cone alignment

rollers (2)

b. Check roller track rollers for damage, b. Any rollers

loose or missing hardware or rollers.

damaged, loose, or

missing hardware or

rollers.

c. Any damage,

c. Check cone alignment rollers for

loose, or missing

damage, if loose, or if missing.

cone alignment

NOTE

rollers.

If rear pin wheel drive mounting

bolts are loose, notify field

maintenance to tighten.

52

During

Rear pinwheel

a. Check rear pinwheel drive for

a. Any damage,

drive (4),

damaged, loose, or missing hardware

loose or missing

hydraulic

and Class III oil leak.

hardware, or Class

motor (5), stop

III oil leak.

cylinder (1), and

b. Any damage or

hydraulic lines

b. Check hydraulic motor and brake for

(7)

loose or missing

damage or loose or missing hardware.

hardware.

c. Any Class III

c. Check hydraulic lines and fittings for

leaks noted.

damage or leakage.

3

4

2

1

5

~

6

7

Pallet assembly

53

After

Check for leaks and any visible damage.

END OF WORK PACKAGE

0043 00-28