TM 5-5420-280-23&P

0030 00

BRIDGE AND PALLET CRACK DEFORMATION INSPECTION AND REPAIR (Contd)

NOTE

GDSBS recommend after any welding, post heat treatment. If there

is no possibility to perform a post-heat treatment, natural aging of

30 days at 68 F (20 C) is also permitted. Natural aging may cause

a high risk of stress corrosion cracking.

j.

If heat treated, welding repair must be heated for 24 hours at a temperature of 257 41 F

(1255 C). Welded component must be subjected to heat treatment for the following reasons:

(1) To relieve inherent stresses.

(2) To restore original strength.

(3) To restore resistance to exfoliation corrosion and stress corrosion cracking.

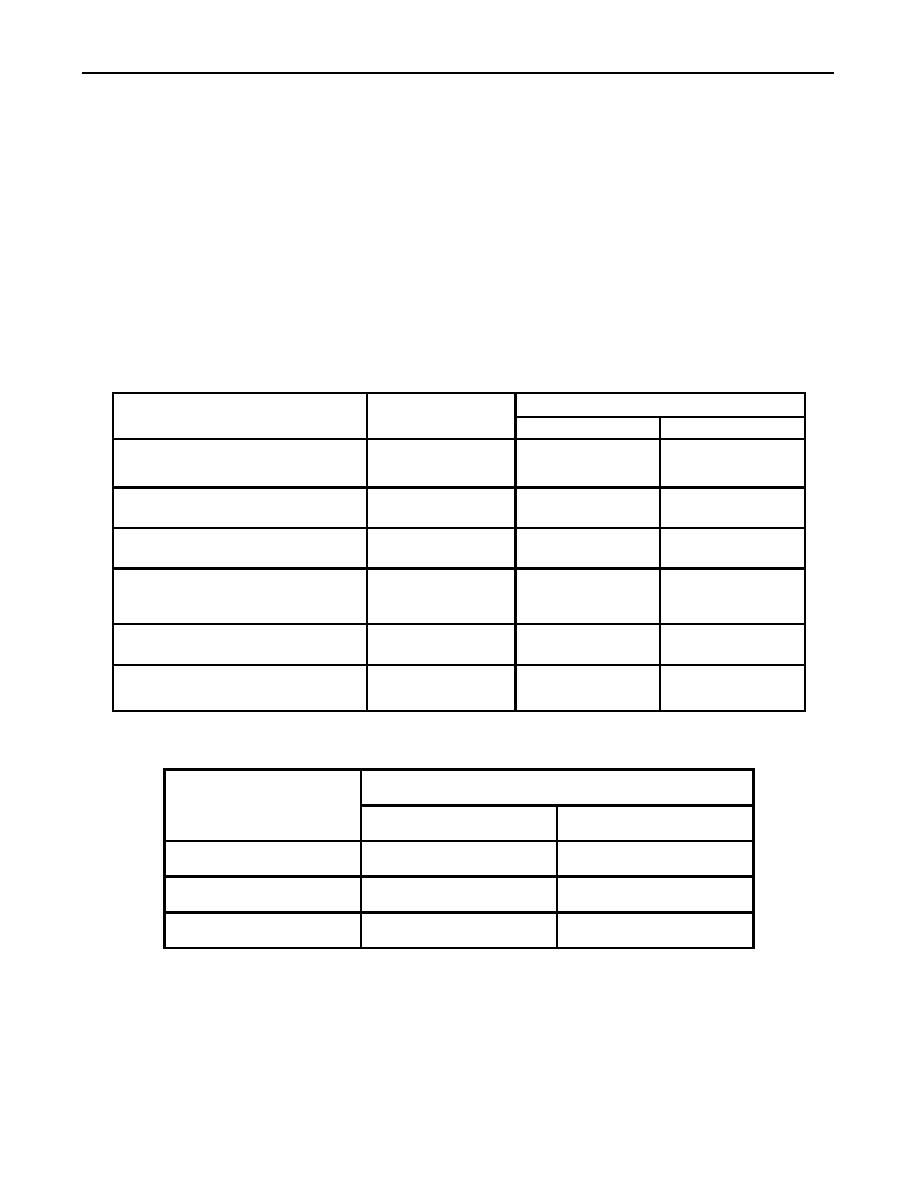

Table 2. Critical Crack Length.

SENTENCING

CRACK LOCATION

TYPE OF INSPECTION

UNDER OBSERVATION

UNSERVICEABLE

Bridge top deck, underside and

1.181 in.

3.150 in.

Visual

ramp end (roadway)

(30 mm)

(80 mm)

Girder top &

0.787 in.

2.362 in.

Visual

Bottom middle and ramp

(20 mm)

(60 mm)

Square tubes

0.984 in.

2.362 in.

Visual

Front & crossgirders

(25 mm)

(60 mm)

Side outer plates

1.181 in.

4.724 in.

Visual

Side outer middle and ramp plates

(30 mm)

(120 mm)

Coupling receptacle

Visual or with x 10

0.236 in.

0.472 in.

and connector

magnifying aid

(6 mm)

(12 mm)

Support rail areas and side plates

0.394 in.

1.181 in.

Visual

at coupling area

(10 mm)

(30 mm)

Table 3. Critical Crack Length.

(measurement on width or height of part)

SENTENCING

LOCATION

UNDER OBSERVATION

UNSERVICEABLE

Roadway

0.591 in. (15 mm)

0.984 in. (25 mm)

Bottom Girder

0.276 in. (7 mm)

0.472 in. (12 mm)

Side sheet

0.315 in. (8 mm)

0.591 in. (15 mm)

.

0030 00-4