TM 5-5420-280-23&P

0015 00

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (Contd)

Table 1. Preventive Maintenance Checks and Services for Pallet.

ITEM

ITEM TO

EQUIPMENT NOT

INTERVAL

PROCEDURE

NO.

CHECK/ SERVICE

READY/AVAILABLE IF:

1

Annual

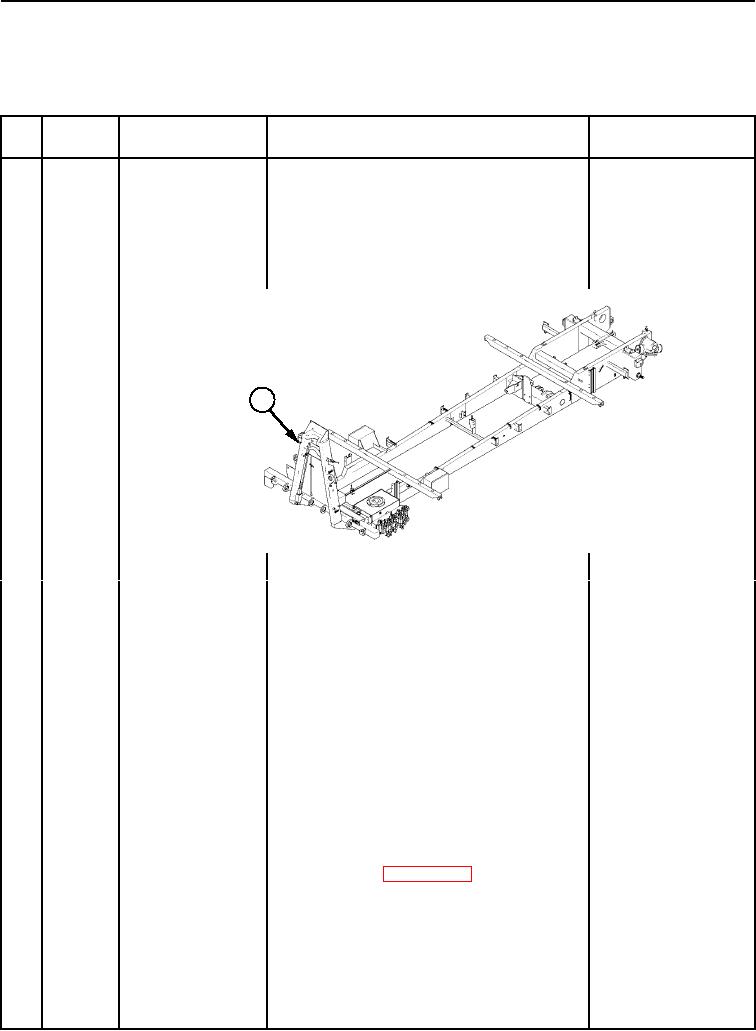

A-frame (1)

Check for cracks, broken welds, or if bent.

Pallet A-frame

member is cracked,

has broken welds, or is

bent enough to affect

operation.

1

2

Annual

Control valves (4),

a. Check control valves for loose mounting

a. Any mounting

manifolds (5),

hardware or oil leakage.

hardware is loose, or

Class III leak is

hydraulic lines (2),

noted.

and solenoid

electrical leads (3)

b. Any mounting

b. Check manifolds for loose mounting

hardware or oil leakage.

hardware is loose, or

Class III leak is

noted.

c. Any Class III is leak

c. Check hydraulic lines for oil leakage.

noted.

d. Any electrical lead

d. Check solenoid electrical leads for damage,

is damaged, loose, or

loose connectors, or frayed wires.

frayed.

e. Repair or replace loose or damaged leads or

wires. Refer to WP 0053 00.

Change 1

0015 00-4