TM 5-5420-280-23&P

0118 00

TORQUE LIMITS (Contd)

TUBING APPLICATION TIGHTENING ASSEMBLY INSTRUCTIONS (Contd)

COPPER TUBING

1. Slide nut and then sleeve on tubing. Threaded

FOR HAND AIRBRAKE

end of nut (B) must face out.

2. Insert tubing into fitting. Ensure tubing is

B

bottomed on fitting shoulder.

3. Thread nut onto fitting body until it is hand

tight.

4. From that point, tighten with a wrench the

number of turns indicated at right.

TUBE

ADDITIONAL NUMBER

SIZE

OF TURNS FROM HAND TIGHT

1-3/4

1-3/4

3-1/4

3-1/4

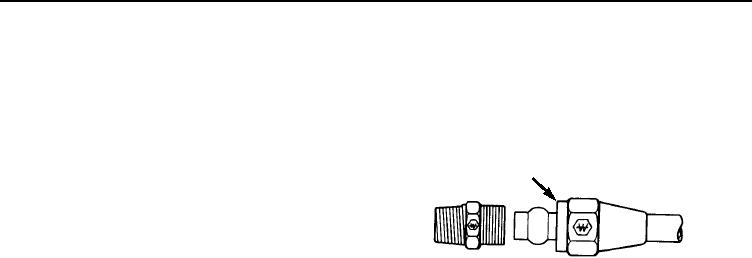

TORQUE WRENCH ADAPTERS

Some maintenance tasks require the use of a torque wrench adapter when the nut or screw cannot be

reached with a regular socket on the end of the torque wrench. These adapters add to the overall length of

the torque wrench and make the dial or scale reading less than the actual torque applied to the nut or

screw. To prevent overtightening and damage to equipment, calculate the correct dial or scale reading using

the conversion formula provided; refer to Conversion Formula in this WP.

0118 00-6