TM 5-5420-278-24&P

0018 00

0018 00-10

Table 1. Unit Preventive Maintenance Checks and Services for Ramp Bay (Contd).

ITEM TO

ITEM

CHECK/

EQUIPMENT NOT

NO.

INTERVAL

SERVICE

PROCEDURE

READY/AVAILABLE IF:

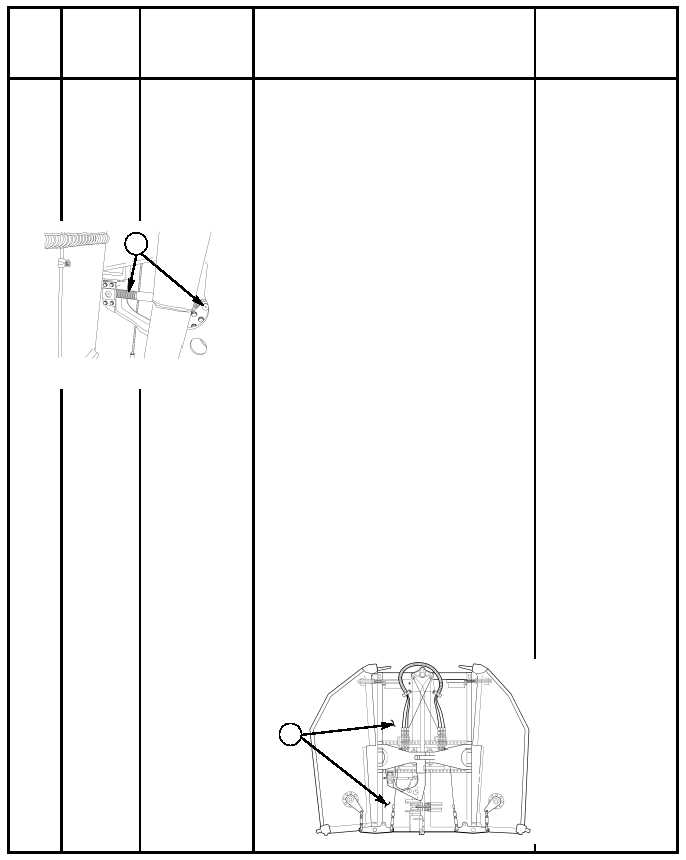

2

15

Semi-

Lower lock-

annually

drive

assembly (1),

cylinder, and

yoke

a. Inspect jackscrew threads for cracks,

burrs, nicks, and deformation.

b. Inspect trunnions and pin for cracks.

c. Inspect bumpers and support brackets

for cracks, broken welds, and deformation.

d. Inspect cylinders for leaks.

e. Inspect hoses and fittings for cracks,

compression, and leakage.

f. Ensure cylinder functions properly in

conjunction with hand pump.

g. Inspect for cracks, deformation, and

elongation of eye.

a. Jackscrew will

not extend or

retract pin properly.

b. Cracks or broken

welds noted.

c. Cracks, broken

welds, or

deformation noted.

d. Any Class III

fluid leak noted.

e. Any Class III

fluid leak noted.

f. Cylinder does not

function properly.

g. Cracks noted or

deformation

prevents proper

operation. Hole

elongation greater

than 50% of hole

diameter noted.

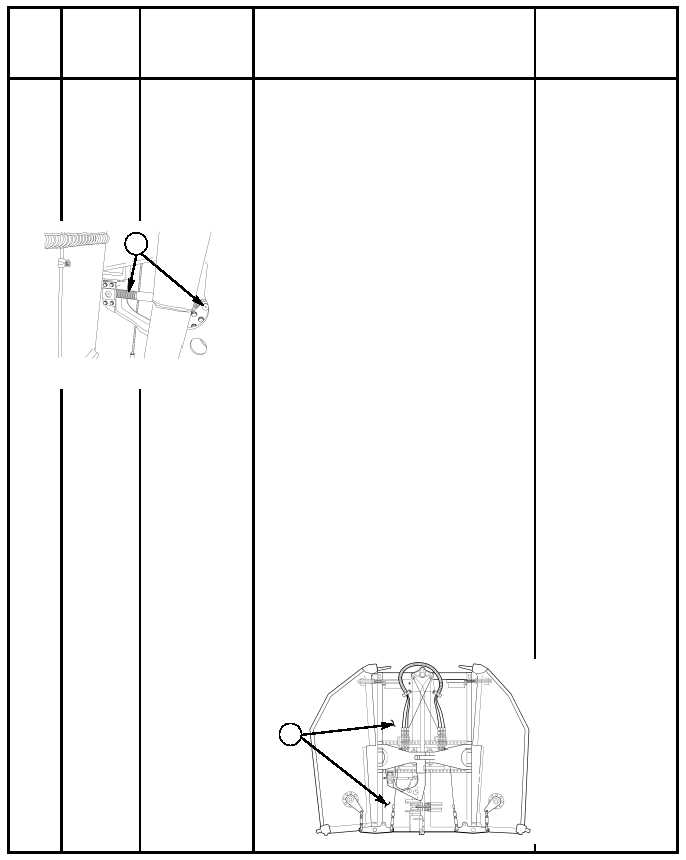

16

Semi-

Right front

annually

outer ponton

end skin

surface (2)

a. Inspect surface area for punctures,

holes, tears, seam ruptures, cracks, and

broken welds.

b. Inspect seams for cracked or broken

welds.

a. Damage which

cumulatively adds

up to a hole

approximately

.26 in. (.66 cm) in

diameter (the size of

a typical pen or

pencil).

b. Cracked or

broken welds noted.

1