TM-5-5420-279-10

1.1.4.4

The palletized loads are then positioned at both sides of the launch vehicle in readiness

for bridge building.

1.1.4.5

The vehicle must be leveled by the A-frame and crane stabilizers and pinned in position

before the crane operator retrieves a section of launch beam. The beam section is then

connected to the forward launch beam section by inserting pins through the jaws at the

top and then bottom of launch beam sections. A guide system on the launch beam aids in

the alignment of the jaws to facilitate pin insertion.

1.1.4.6

As the launch beam is boomed out across the gap, the crane operator retrieves and

places in position the next section of the launch beam. The sequence continues until the

launch beam assembly is complete, with eight sections being required for the full span.

The launch frame articulator cylinders then lower the launch beam far end until the far

bank support contacts the ground to support the assembled beam. The far bank support

is self-leveling and does not require any manual intervention.

1.1.4.7

During bridge deployment, the location of the palletized loads, and thus the modular

bridge sections, is critical to the speed of the operation. This sequence is given in detail

later in this manual.

1.1.4.8

The articulator cylinders are detached from the slide frame cross member and stowed

under the launch frame by the articulator stow cylinders. The upper A-frame beam is then

raised and pinned in the bridge deployment position, and the A-frame support struts are

lowered. This provides clearance for the modular bridge sections to be launched through

the A-frame.

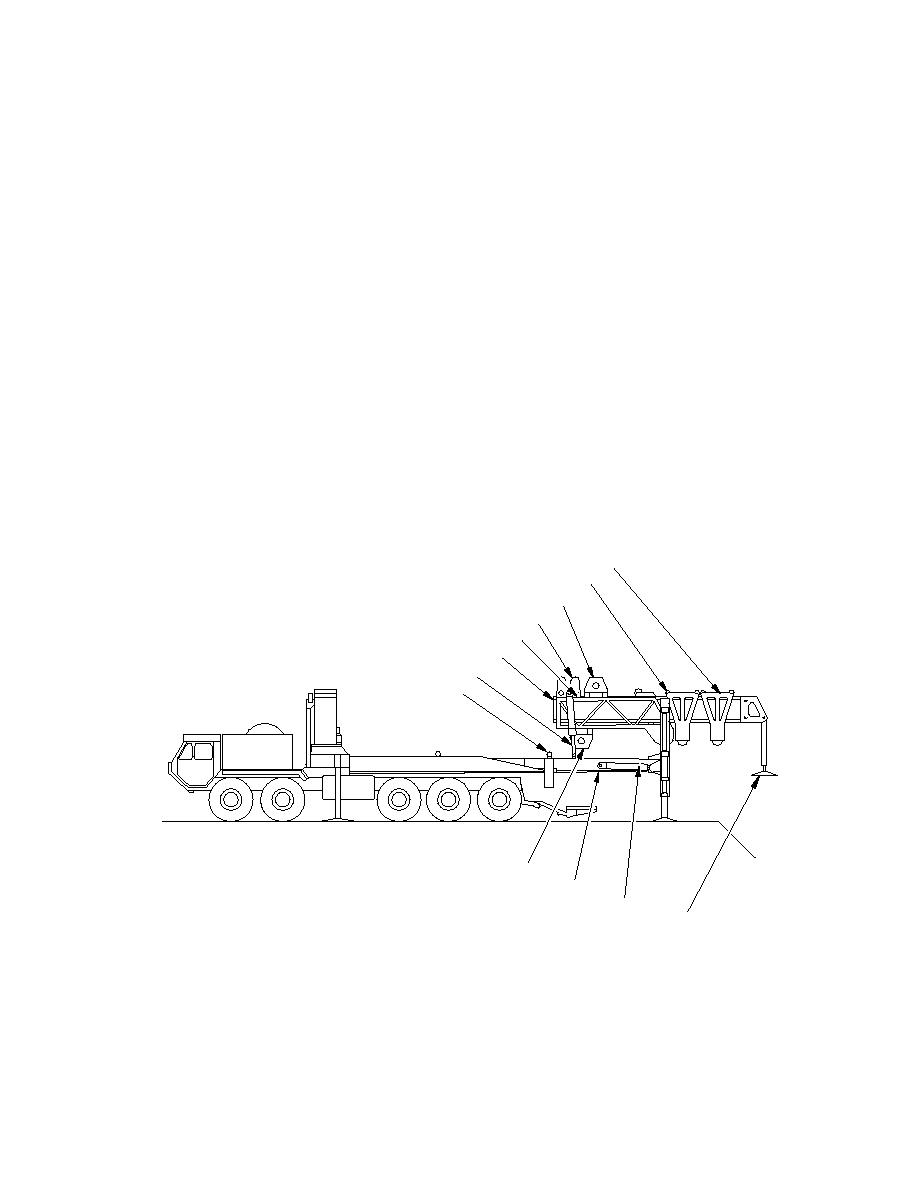

FAR BANK CARRIAGE

HOME BANK CARRIAGE

UPPER WINCH

LAUNCH BEAM DRIVE

LAUNCHING FRAME

FORWARD LAUNCHING BEAM

LAUNCHING FRAME ARTICULATOR

TILT ROLLERS

LOWER WINCH

SLIDE FRAME ASSEMBLY

`A' FRAME ROTATE CYLINDER

FAR BANK SUPPORT

WF/0002

Figure 1.2 Launcher Vehicle Extended

1-5