TM-5-5420-279-10

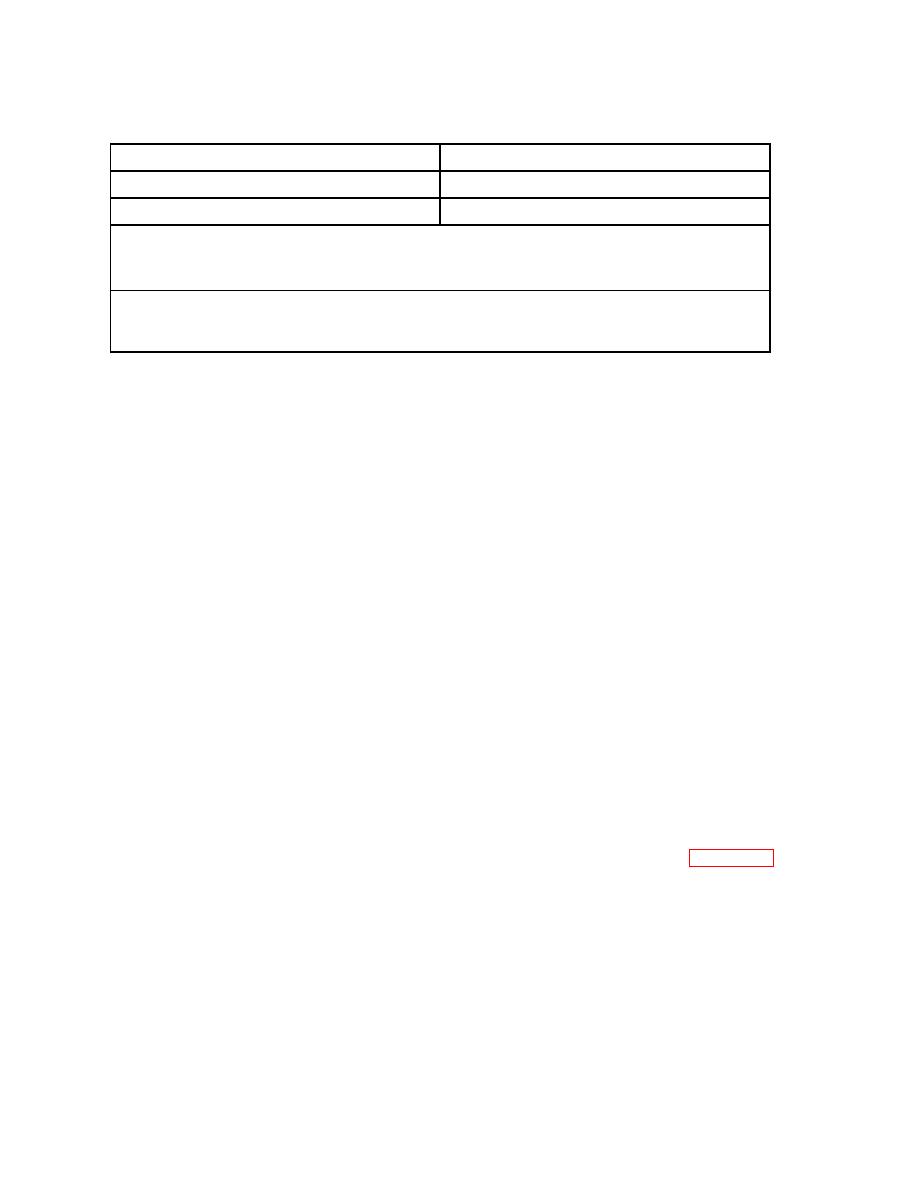

VEHICLE WEIGHT

CROSSING SPEED

Up to MLC 30

25 mph (40 kph)

Above MLC 30

15 mph (25 kph)

Exceptions:

Vehicles with low ground clearance such as the Abrams mine plow must be limited to a crossing

speed of 10 mph (16 kph).

Vehicles with large front or rear overhangs must approach and exit the bridge with

caution and at a slow speed to prevent contact with, and subsequent damage to the

bridge.

1.1.3.2

The complete system is capable of constructing two 20 m bridges.

1.1.3.3

A launcher attached to the transport vehicle consists of a crane, a slide frame, a launch

frame and a fold out A-frame for leveling and stabilization. The crane is operated

separately while the launcher is operated via hydraulic circuits controlled from a chest

pack. The chest pack includes two joysticks and illuminated panels to indicate the current

action being or about to be executed. Leads, from a control cabinet on the vehicle,

terminate at either end of the vehicle to facilitate connection of the chest pack lead.

1.1.3.4

The launch frame also carries the first section of the launch beam upon which the far bank

and home bank carriages, used to support the bridge sections during assembly and

placement, are already in place. The launch frame features a launch beam drive unit to

move the launch beam forward or rearward as required. Winches attached to the launch

frame, control the movement of the carriages and the raising or lowering of the bridge

during deployment and recovery.

1.1.3.5

The A-frame consists of foldout support legs that allow the vehicle to be leveled and

stabilized for bridge deployment and an upper beam that supports the launch frame. This

upper beam is used in its lower position for launch beam deployment and is raised to

provide clearance for the modular bridge sections during bridge deployment.

1.1.3.6

The operation of the drive mechanism, winches and hydraulic cylinders is controlled via

the chest pack. The operator of the chest pack controls the whole bridge deployment

operation, which relies on coordinated actions of the 8-man crew in order to achieve

minimum deployment times.

Basic Operational Sequence (Deployment)

1.1.4.1

Upon arrival at the crossing, the build site is marked out in accordance with Figure 1. 12.

1.1.4.2

All vehicles are driven to the staging area and a number of palletized loads ground

loaded.

1.1.4.3

The launch vehicle is then partially prepared for use. The tail-lift is opened, the crane

partially deployed and the A-frame unfolded and pinned. The launch vehicle is then

guided to the predetermined set back distance from the bank edge using the tire

alignment marks. This provides clearance and support for the bridge when it is lowered

into position. The A-frame stabilizer legs are extended to raise the launcher clear of the

rear of the vehicle. The launch vehicle is then driven forward to extend the slide frame.

With the slide frame fully extended the crane can be fully deployed.