TM 5-5420-280-23&P

0030 00

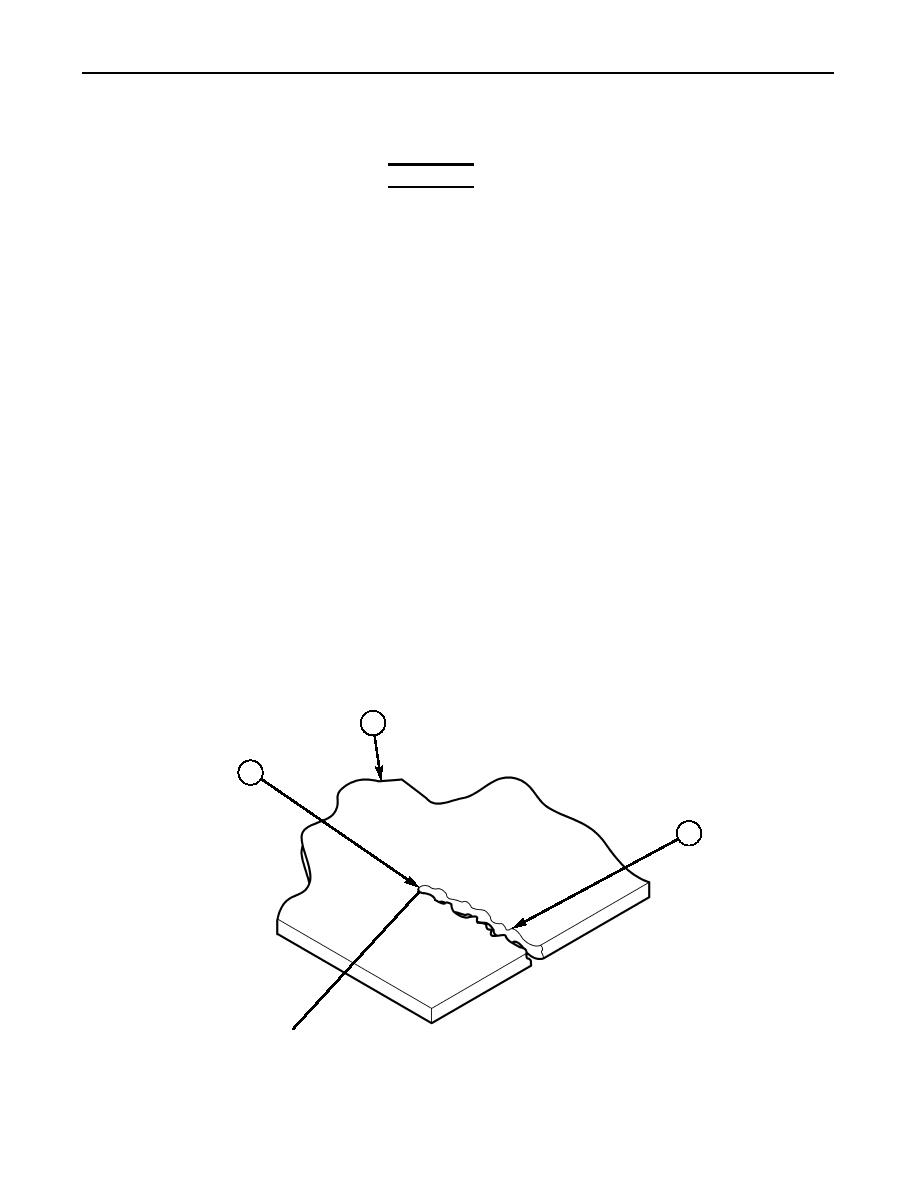

BRIDGE AND PALLET CRACK DEFORMATION INSPECTION AND REPAIR (Contd)

WARNING

Welding repair of bridge structural components is not

allowed at field level. Attempting welding repair of

damaged structural areas without proper heat treating will

compromise strength of bridge. Failure to comply may

result in failure of bridge, damage to equipment, and

possible injury or death to personnel.

NOTE

If there are several cracks or holes within a damaged area,

repair must be performed by removing damaged area and

welding in a new sheet metal plate, P/N AMS-QQ-A-25014,

NSN 9535-00-003-6946.

REB are made from Aluminum Alloy EN AW7020 to

EN-755, EN-485 etc.

PREPARATION

1.

Position bridge (1) so crack (2) is face-up for welding.

2.

Grind area and find ends of crack (2).

3.

Drill a hole (3) at ends of crack (2) in order to prevent enlargement of crack (2). Use a drill

with diameter corresponding to half the plate thickness.

NOTE

If crack is open 0.098 in. (2.5 mm) or more, and additional

permanent weld pool retainer is required. For this retainer,

use a metal strip 1 in. (25.4 mm) or more in width and with

a milled groove.

4.

Mill or grind a V-seam along crack (2) with a groove angle of 70 degrees.

5.

Clean area to be welded with a stainless steel wire brush.

1

3

2

DRILL BIT SIZE IS EQUAL TO

HALF THE PLATE THICKNESS

0030 00-13