TM 5-5420-280-23&P

GENERAL MAINTENANCE INSTRUCTIONS

RAPIDLY EMPLACED BRIDGE (REB)

NSN 5420-01-481-3959 P/N 12480471

TORQUE LIMITS

GENERAL

This work package provides general torque limits for screws used on the Rapidly Emplaced Bridge

(REB). Special torque limits are indicated within the maintenance tasks for applicable components. The

general torque limits given in this work package shall be used when specific torque limits are not indicated

in the maintenance task. These general torque limits cannot be applied to screws that retain rubber

components. Rubber components will become damaged before the correct torque limit can be reached.

TORQUE TABLES

Table 1 lists dry torque limits. Dry torque limits are used on screws that do not have lubricants applied

to the threads. Table 2 lists wet torque limits. Wet torque limits are used on screws that have high pressure

lubricants applied to the threads. For metric fasteners, refer to table 3 for torque limit requirements.

HOW TO USE TORQUE TABLES

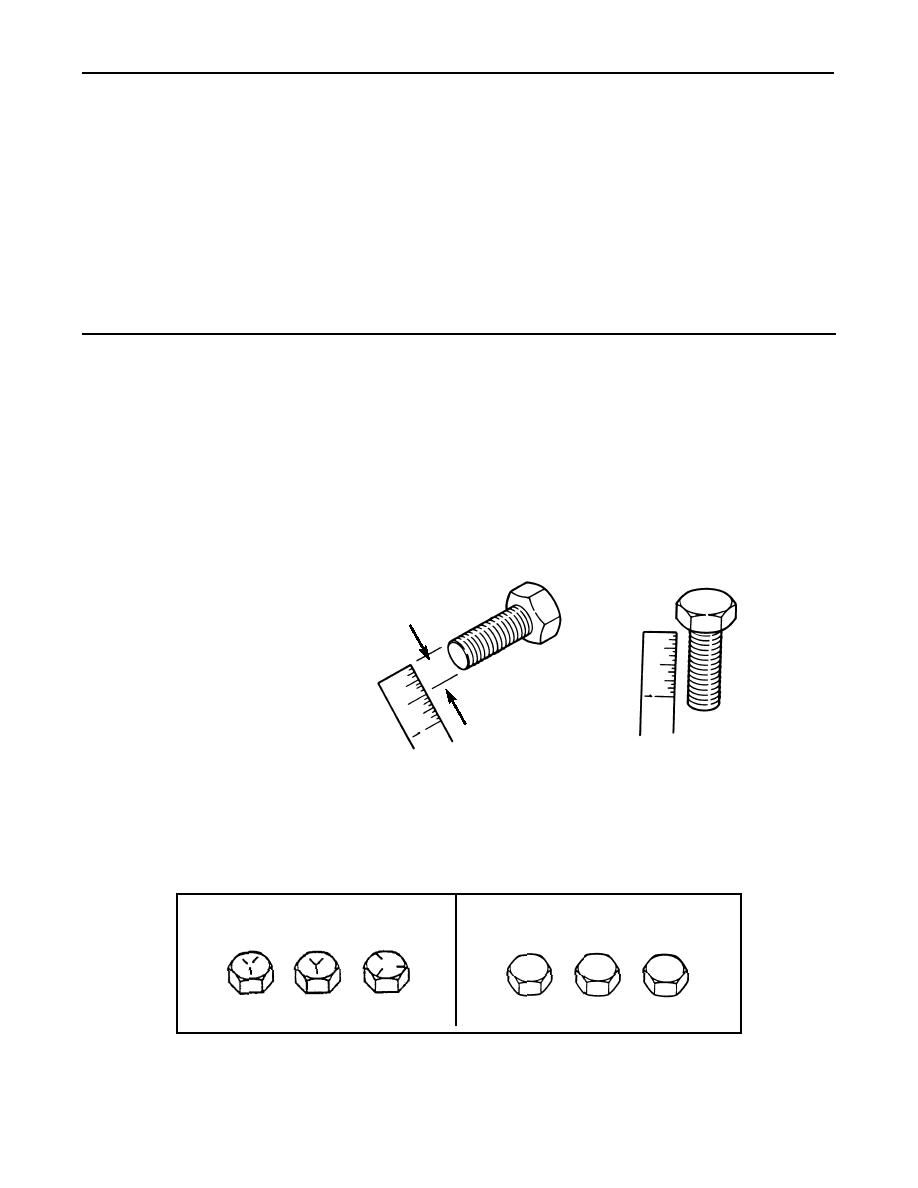

1.

Measure the diameter of the screw.

2.

Count the number of threads per inch.

3.

Under the heading SIZE, look down the left hand column and find the diameter of the screw. (There

will usually be two lines beginning with the same size).

4.

In the second column under SIZE, find the number of threads per inch that matches the number of

threads you counted in step 2. (Not required for metric screws).

5.

Determine the grade of screw by matching the markings on the head of the screw to the correct

picture of CAPSCREW HEAD MARKINGS in the illustration preceding the torque limits table.

Screws shown are all SAE Grade 5 (3-line). Metric screws can be three grades: 8.8,

10.9, and 12.9. Grades and manufacturer's

Metric screws can be three grades: 8.8,

marks appear on the screw head.

8.8

10.9

12.9

STANDARD

METRIC

6.

Look down the column under the picture you found in step 5. until you find the torque limit (in lb-ft or

N.m) for the diameter and threads per inch of the screw.