TM 5-1940-322-24

0006 00

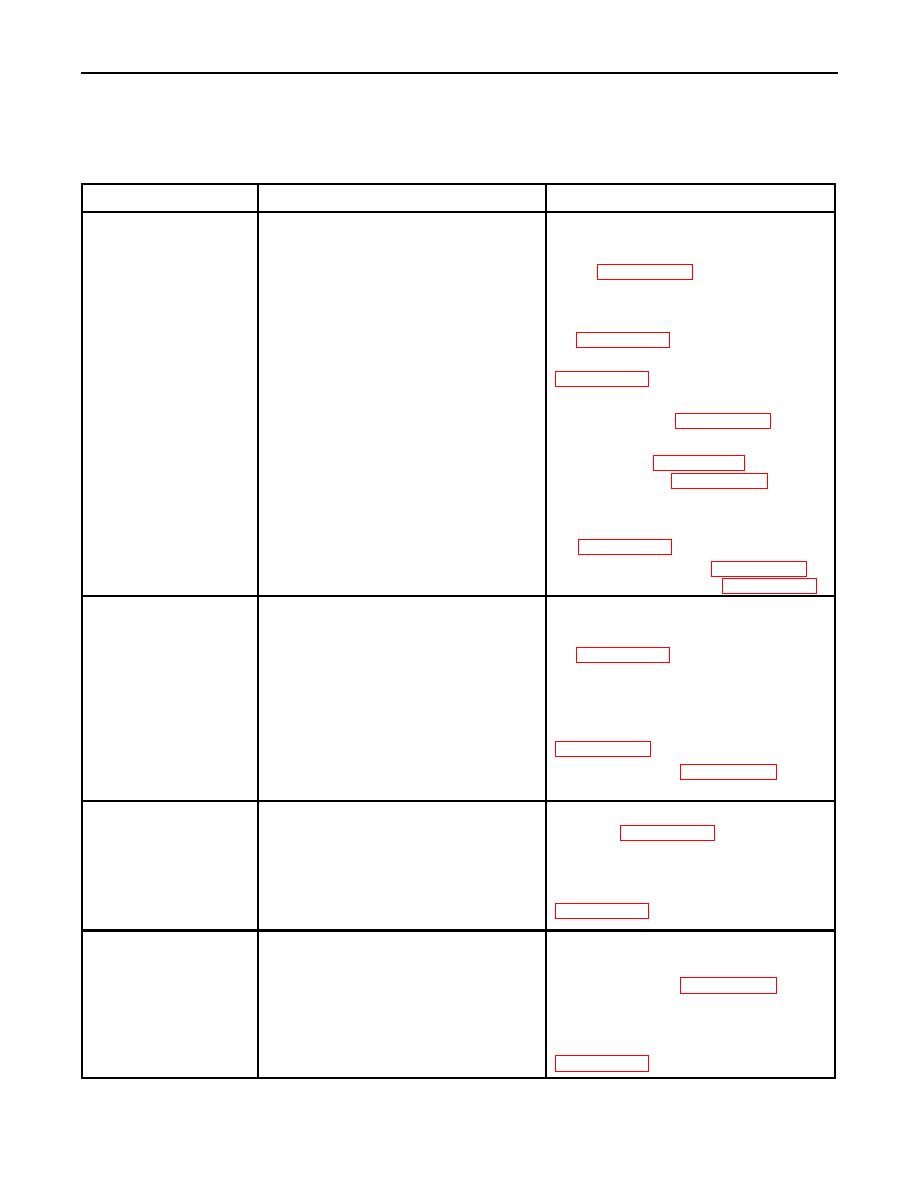

MECHANICAL SYSTEMS TROUBLESHOOTING (Contd)

Table 1. Engine Troubleshooting Procedures (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Check position of engine control stop

Push in engine control stop handle and

2. ENGINE CRANKS

ensure that cable is not broken and is

handle and cable.

BUT FAILS TO START

functioning properly at fuel injection

pump (WP 0032 00).

2. Check fuel level in supply tank.

1. Fill fuel supply tank if empty.

2. Bleed the fuel system after refueling

3. Check for fuel at engine (ensure fuel Bleed fuel system if air present

is at aft injector).

4. Check air cleaner for restrictions.

Remove restrictions and replace air

cleaner if needed (WP 0104 00).

5. Check fuel for contamination.

Drain supply tanks and clean or replace

all fuel filters (WP 0073 00) and fuel

water separators (WP 0076 00).

6. Check for continuity to fuel shut-off

1. Repair defective wires.

2. Replace injection pump

7. Check for malfunctioning fuel lift

Replace fuel lift pump (WP 0103 00)

pump or fuel injection pump.

and fuel injection pump (WP 0102 00).

1. Check fuel level in supply tank.

1. Fill fuel supply tank if empty.

3. ENGINE STARTS

BUT WILL NOT

2. Bleed fuel system after refueling

KEEP RUNNING

2. Check engine stop cable and lever

Move stop cable and lever to full

for full forward position.

forward position. Inspect stop cable

and lever for proper operation.

3. Check for plugged fuel lines or

Drain fuel water traps and filters

filter.

4. Check fuel system for air leaks.

Bleed fuel system (WP 0080 00) and

tighten all fittings and lines.

1. Check engine circuit switch for

Replace engine circuit switch if

4. ENGINE WILL NOT

damaged (WP 0041 00).

damage.

SHUT OFF

Adjust fuel shutoff cable and lever.

2. Check fuel shut-off cable and lever

for full rear position.

Replace blocking diode if defective

3. Check blocking diode for loose

connections.

1. Check high pressure fuel line for

Tighten high pressure fuel lines.

5. ENGINE IDLES

leaks.

ROUGH WHEN

WARM

2. Check for air in fuel lines.

Bleed fuel system (WP 0080 00) and

tighten all lines.

3. Check if idle speed is low.

Adjust idle speed to 650750 rpm.

4. Check for plugged fuel injector

Remove, clean or replace fuel injectors

nozzles.