TM 5-1940-322-24

0007 00

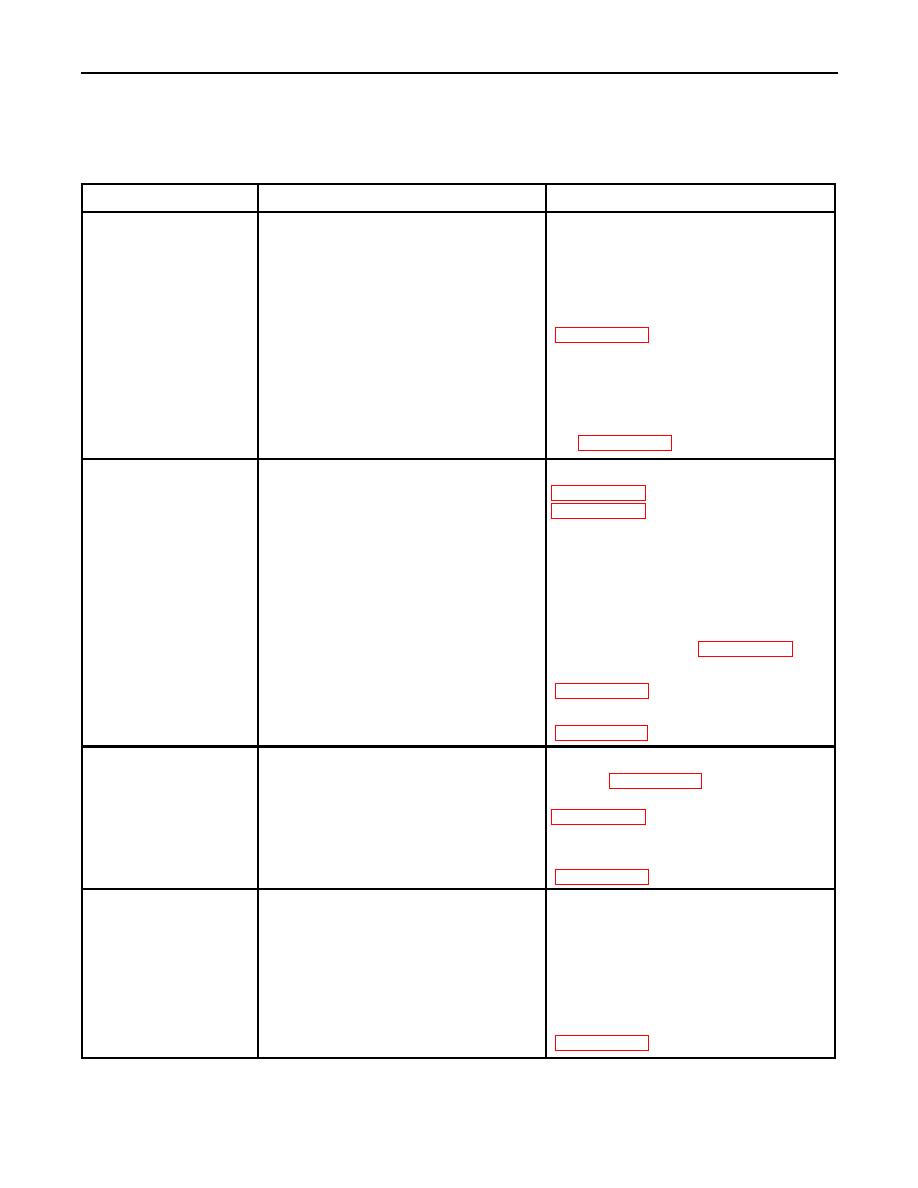

ELECTRICAL SYSTEMS TROUBLESHOOTING (Contd)

Table 1. Electrical Troubleshooting Procedures (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Check engine circuit switch.

1. Turn switch to ON position.

2. ONE OR BOTH

WARNING LIGHTS

2. Test switch, if switch is defective

DO NOT COME ON

replace.

(MASTER SWITCH ON)

2. Inspect engine circuit fuse.

If defective, replace fuse.

3. Test battery for load.

If defective replace battery

(TM 9-6140-200-14).

4. Check battery connections and

1. Clean battery posts and cable

cables.

connector leads.

2. Tighten cable leads.

3. Replace defective cables

1. Inspect individual lamps.

Replace defective lamps. Refer to

3. INDIVIDUAL LIGHTS

INOPERATIVE

lamp, and navigational lamps.

2. Check lamp sockets for corrosion.

1. Remove corrosion from lamp

sockets.

2. If corrosion is not present, check

spring action of lamp socket

terminals. If terminal springs are

defective, replace (WP 0057 00).

3. Test circuit fuse on control panel.

If fuse is defective, replace

4. Test switch on control panel.

If switch is defective, replace

1. Test individual sending unit.

If sending unit is defective, replace.

4. INSTRUMENT

Refer to WP 0094 00 for water

PANEL GAUGE

2. Test for continuity & voltage

temperature sending unit and

INOPERATIVE

present at gauge.

(WATER TEMPERATURE

unit.

AND OIL PRESSURE)

3. Check individual gauge for

If gauge is damaged, replace

damage.

Check operation of water temperature

5. WATER

sending unit.

TEMPERATURE

GAUGE

1. Verify voltage is present.

If voltage is not present inspect cable

INOPERATIVE

and cable connection for damage,

replace cable if damaged.

2. Verify water temperature sending

If water temperature sending unit is

unit is operating properly.

not operating properly, replace