TM 5-1940-322-24

0142 00

HYDROJET ASSEMBLY MAINTENANCE (Contd)

INSTALLATION (Contd)

CAUTION

Take care when installing hydrojet assembly through opening in

transom, or when lowering hydrojet assembly down onto base plate

studs. Failure to comply may result in damage to equipment.

4.

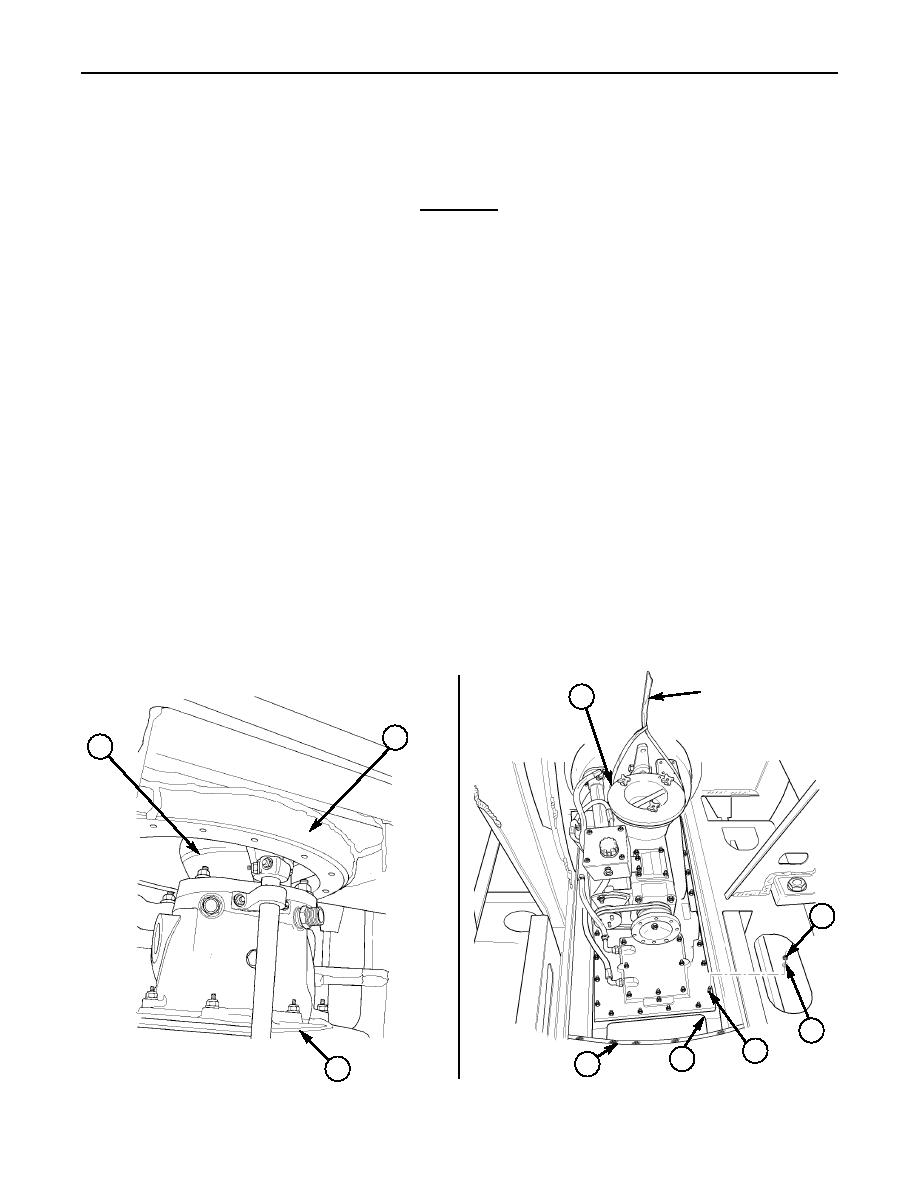

Install hydrojet assembly (3) through opening in transom (2), tilting as necessary. Slowly move

hydrojet assembly (3) rearward and position hydrojet steering deflector (1) through opening in

transom (2).

5.

Lower hydrojet assembly (3) onto base plate (7) and studs (6).

6.

Install twenty-six washers (5) and new locknuts (4) on studs (6). Tighten locknuts (4) to 2325 lb-ft

(3134 Nm).

7.

Remove lifting device and lifting strap from hydrojet assembly (3).

8.

Connect drain down hose (8).

NOTE

Ensure excess silicone rubber adhesive materials are removed from

intake prior to installing hydrojet grill.

9.

Apply light coat of sealing compound (243) to studs (9) on underside of hydrojet housing (10) and install

intake grill (11) on hydrojet housing (10) and studs (9) with washers (13) and new locknuts (12). Tighten

locknuts (12) to 4448 lb-ft (6065 Nm).

10.

Apply light coat of silicone rubber adhesive to twelve screws (16), around opening on transom (2), and

on mating side of transom flange (15).

11.

Install new gasket (14) and transom flange (15) on transom (2) with twelve insulator washers (18),

washers (17), screws (16), washers (19), and new locknuts (20). Tighten locknuts (20) evenly in star

pattern to 23 lb-ft (31 Nm).

LIFTING SLING

3

2

1

~

4

5

6

7

8

3

0142 00-8