TM 5-5420-202-20-3

COMPENSATING IDLER ARM ASSEMBLY REPAIR (Sheet 5 of 5)

7.

Remove bearing inserter from upper spindle.

8.

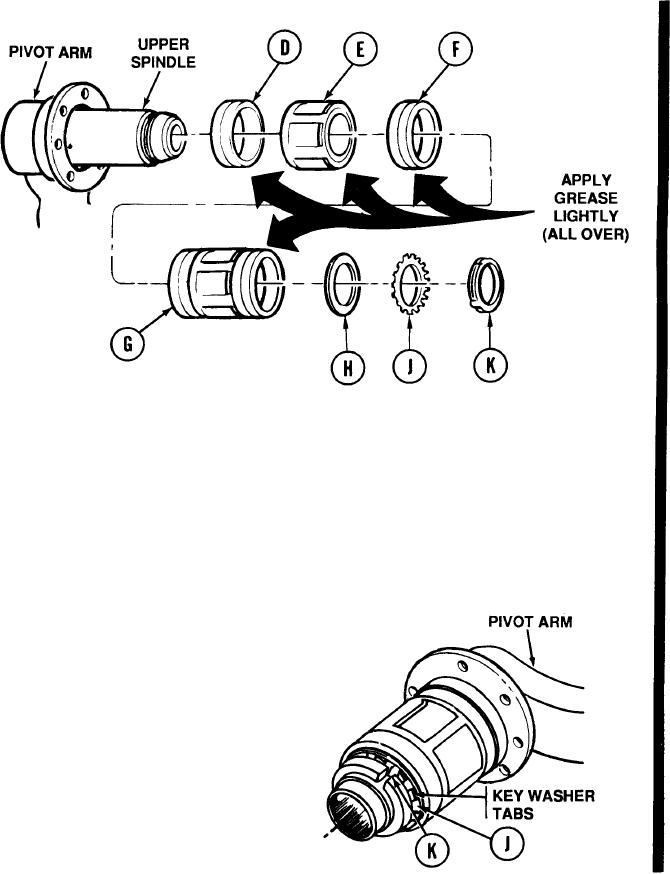

Apply light coat of grease to outer bearing (D), bearing spacer (E), and inner bearing (F) or to spacer

assembly (G). Install on arm upper spindle.

9.

Install bearing washer (H), key washer (J) with tabs toward nut (K), and screw nut (K) onto end of upper

spindle.

10. Using spanner wrench and hinged handle, tighten nut (K) until bearing assembly cannot be turned.

11.

Back nut (K) off just enough so bearing assembly can be turned by hand through one complete turn on

spindle.

12.

Using hammer and punch, bend a tab of key

washer (J) so it fits in one of four slots in nut

(K).

13.

Service hub and arm assembly (LO 5-5420-202-

12).

14.

Install compensating idler arm assembly (page

1418).

End of Task

Change 4

14-69