5-5420-202-20-3

TM

COMPENSATING IDLER ARM ASSEMBLY REPAIR (Sheet 3 of 5)

CLEANING AND INSPECTION:

1.

Clean all parts including bearings.

Minor nicks, scratches, gouges, and pitting are

2.

okay if they are not on machined surfaces.

Inspect bearings and cups for damage. Replace

3.

as necessary.

4.

Check seal assembly for rust, missing rivets, or

other damage. Replace seal where required.

Inspect all nuts, washers, and screws for wear

5.

and damaged threads.

Inspect spacer and bearing sleeve on spindles

6.

for scratches, nicks, or dents. If damaged,

notify support maintenance.

ASSEMBLY:

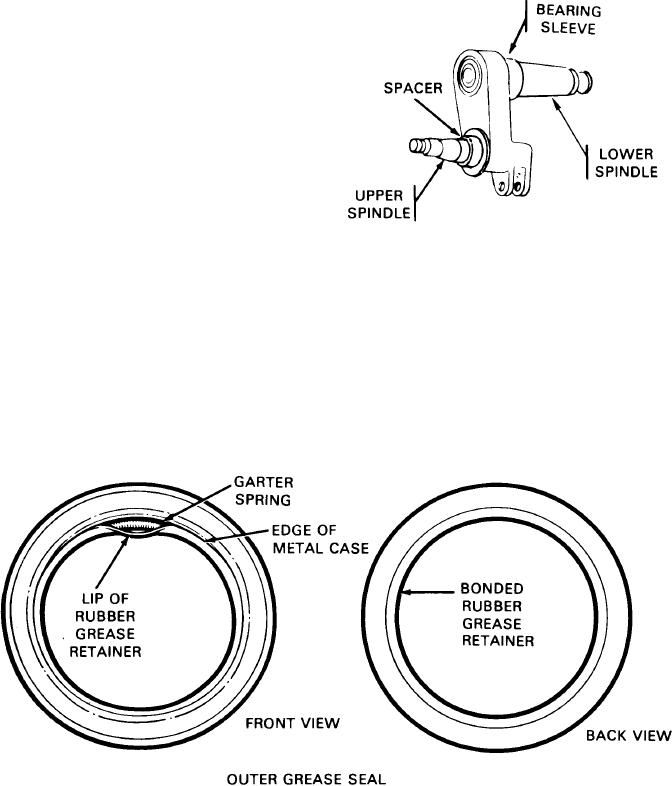

NOTE

Identify FRONT and BACK of outer grease seal.

Rubber

grease seal retaining lip can be pulled away from metal inner

edge on FRONT of seal. Pull back retaining lip on seal and

expose garter spring. BACK of seal has rubber grease retainer

bonded to metal case and cannot be pulled away.

TA249594

Go on to Sheet 4