ARMY TM 5-5420-212-10-1

MARINE CORPS TM 08676A-10/1-1

a.

Pallet Off-Loading: After the marking the se has been completed, the pallets a removed from trucks and

trailers. Pallets may be pulled of trucks and trailers with the aid of an extractor cable, or trucks may

dump pallets by raising the bed.

b.

Pallet Unpacking: Unpacking consists unstrapping pallets and carrying bridge parts to the assembly site.

c.

Assembly: The assembly begins with the construction of the roller beam and ends when the bridge is

open to traffic.

d.

Disassembly: The disassembly begins with the removal of the guide markers and ends when cleaning of

the bridge and erection parts is finished.

e.

Pallet Repacking: consists of carrying the bridge and erection parts from the disassembly site to the

loading site and placing and strapping the parts on their assigned pallets.

f.

Pallet Reloading: Reloading consists of lifting the pallets onto the trucks and trailer.

Section III. OPERATION UNDER UNUSUAL CONDITIONS

This section deals with adverse conditions under which the bridge may have to be launched and the methods of

controlling the launch.

2-3.

LAUNCHING IN HIGH WINDS

a.

When launching with e building area sheltered and the gap exposed, wind loads may cause the bridge to

rotate about the forward roller beam or capsill roller beam, until the bridge is jacked down onto the far bank. Bridges shall

not be launched in more severe conditions than those given below.

TABLE 2-3. Launching conditions

Single Story (SS)

MAXIMUM CONDITION DURING LAUNCH

BRIDGE LENGTH

Double story (DS)

WIND SPEED

CROSS FALL ON

Link Reinforced

(LR)

BRIDGE

4 thru 12 Bay

SS

40mph (65km/ph)

1 in 20*

2E + 1 thru 2E + 12

DS

40mph (65kmph)

1 in 20*

2E + 13 thru 2E + 16

LR

40mph (65km/ph)

no cross fall*

2E + 17 thru 2E + 22

LR

30mph (48km/ph)

no cross fall*

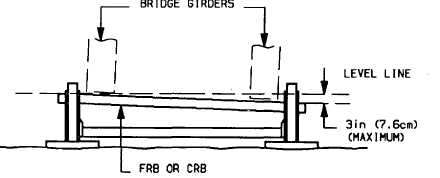

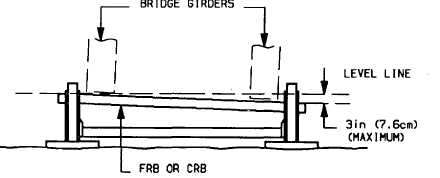

RRB/FRB/CRB shall be approximately [within 3in (7.6 cm)] level when the launching nose has touched

the far bank. See sketch below.

2-4