TM 5-5420-278-24&P

0022 00

0022 00-6

NOTE

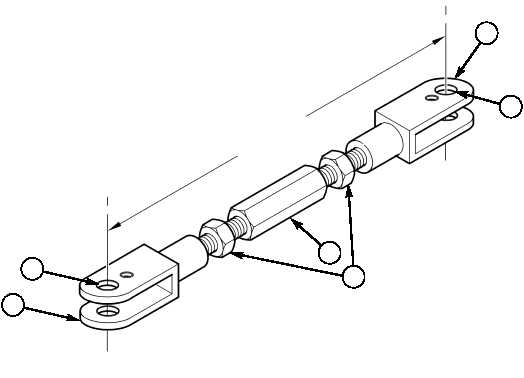

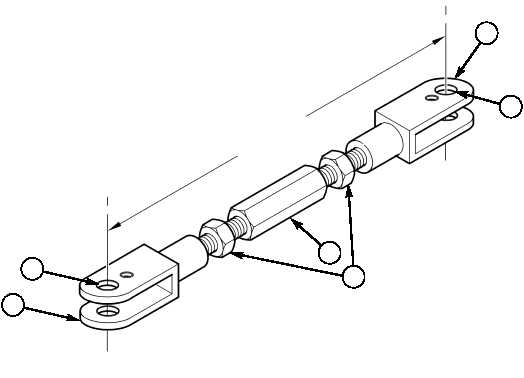

Free threads on turn buckle clevis ends must have the same

number of threads showing ± two threads.

14.

Loosen nuts (3) and pre-set turnbuckle (4) to 13.5 ±0.2 in. (343 ±5 mm) from center of holes (2) by

adjusting turnbuckle cleves ends (1). Do not tighten nuts (3) until turnbuckle (4) is installed.

WARNING

All personnel must stand clear during lifting operations. Ensure

ponton foldlock and travel latches are in good mechanical

condition and securely locked prior to lifting outer ponton. Failure

to comply may result in injury to personnel.

15.

Lift outer ponton (5) and install 3 x 4.7 x 10.8 in. (8 x 12 x 27.5 cm) block (6) in position under

connect link (7) and lower outer ponton (5) until turnbuckle clevis (1) aligns with hole in torsion bar

lever (8), and install turnbuckle clevis (1) on torsion bar lever (8) with pin (9), washer (10), and

screw (11). Remove block (6).

16.

Lower outer ponton (5) down on inner ponton (12) and install pre-stressing tool (13), flat edge

against deck overhang (14), on outer ponton (5) and adjust turnbuckle (4) until torsion bar lever (8)

aligns with pre-stressing tool (13) then tighten two nuts (15). Remove pre-stressing tool (13).

17.

Apply grease to lube fitting (WP 0016 00).

18.

Engage foldlock.

19.

Connect inner pontons (WP 0023 00).

20.

Install ramp bay on transporter (TM 5-5420-278-10).

TORSION BAR REPLACEMENT (Contd)

1

2

2

1

4

3

13.5 ±0.2 in.

(343 ±5 mm)