TM 55-1945-205-10-4

0099 00 48

0099 00

18

After

0.5

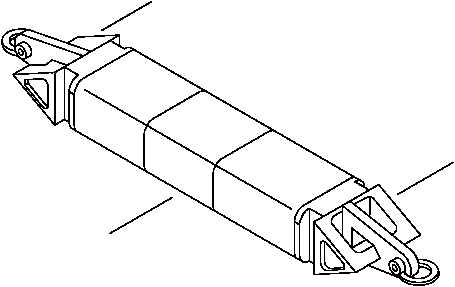

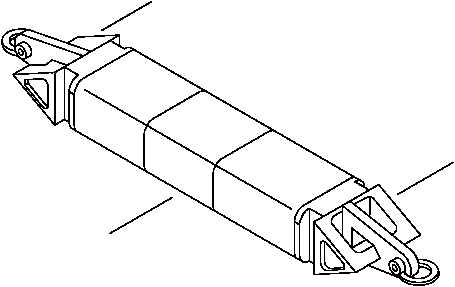

Flexors

1. Inspect uninstalled flexors for

separation of the polyurethane

material in the center. If separation

of the polyurethane material in the

center of the flexor is found, contact

unit maintenance.

Separation of the

polyurethane

material in the

center of the flexor

is found.

2. Inspect uninstalled flexors for

cracks in the external weldments on

the ends. If cracks in the external

weldments on the ends of the flexor

are found, contact unit maintenance.

Cracks are

discovered in the

external weldments

on the ends of the

flexor.

19

After

.4

Non-Powered

Modules

Inspect modules for broken welds,

cracks, punctures and corrosion. If

found, contact unit maintenance.

Inspect all powered and non-

powered modules for major

deformation. If major deformation

or leaks are found, contact unit

maintenance.

Any damage to

deck fittings is

found that would

affect operation.

Major deformation

is found.

20

After

0.2

Lifting Slings

Check lifting slings for cuts, loose

stitching and fraying. If slings are

cut, frayed or have loose stitching,

contact unit maintenance.

Slings are cut, have

loose stitching or

frayed.

Table 1. Preventive Maintenance Checks and Services. (Continued)

ITEM

NO.

INTERVAL

MAN-

HOURS

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

POLYURETHANE SECTION

METAL END

METAL END