TM 5-1940-322-24

0156 00

CRANKSHAFT AND CRANKSHAFT GEAR REPLACEMENT (Contd)

INSTALLATION (Contd)

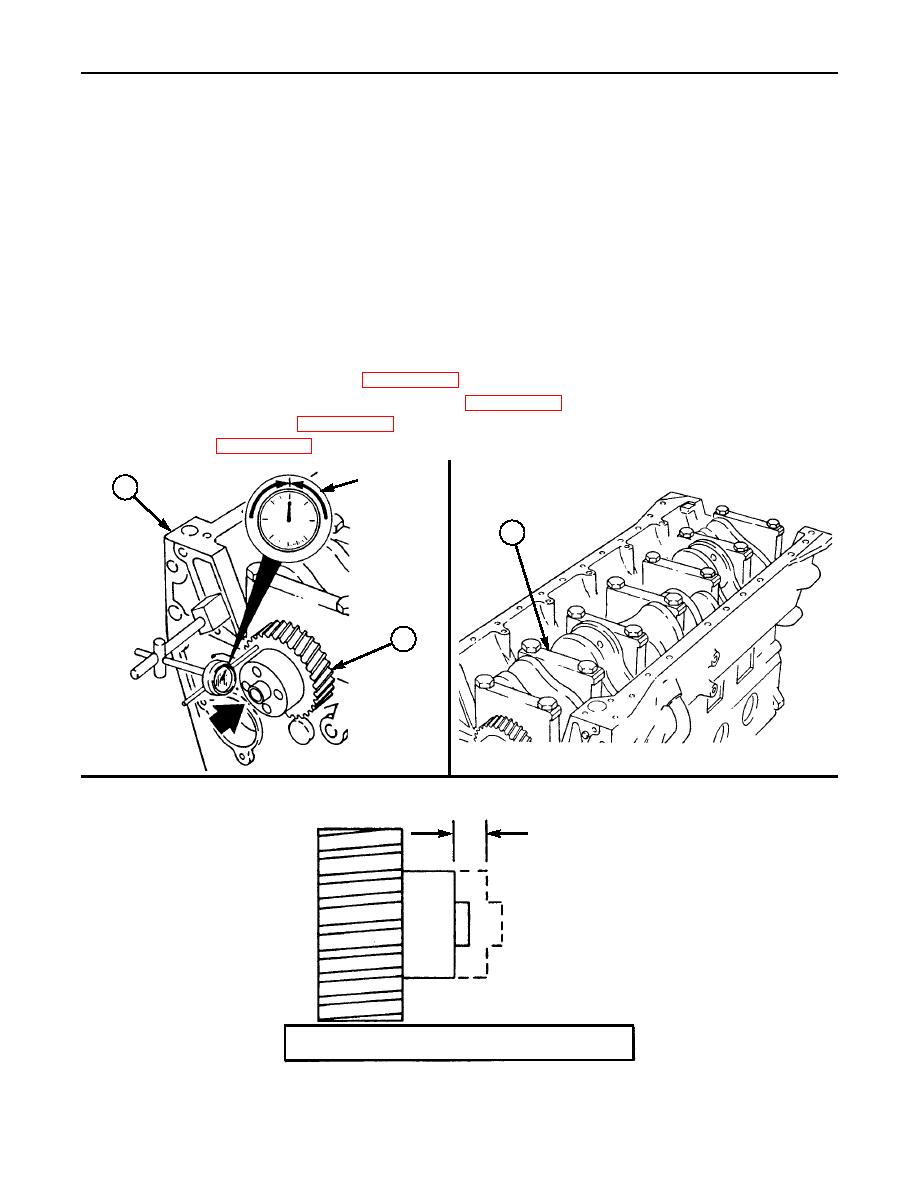

NOTE

Perform steps 12 through 14 if the crankshaft does not rotate

easily.

12.

Turn crankshaft gear (2) 360 to determine that it will rotate freely.

13.

Check main bearing caps (3) and/or bearing sizes if the crankshaft gear (2) does not turn easily.

14.

Push crankshaft gear (2) towards one end of its thrust.

15.

Using dial indicator, zero indicator and push crankshaft gear (2) towards other end of its thrust and

record crankshaft end clearance.

16.

Ensure crankshaft end clearance meets specifications. See figure below for crankshaft end clearance.

17.

Install pistons and connecting rods (WP 0152 00).

18.

Install flywheel, crankshaft rear seal and housing (WP 0157 00).

19.

Install front gear housing (WP 0155 00).

20.

Install engine (WP 0115 00).

DIAL

1

INDICATOR

3

2

CRANKSHAFT END

CLEARANCE

MIN.

0.004 in.

(0.100 mm)

MAX.

0.017 in.

(0.430 mm)

END OF WORK PACKAGE

0156 00-6