ARMY TM 5-5420-212-10-1

MARINE CORPS TM 08676A-1 0/1-1

(7)

Assemble capsill roller beam, and slide under rear of bridge. Center capsill roller beam under bridge at

least 1.5 ft (0.5 m) from end of end taper panel.

(a)

Ensure capsill roller beam is over centerline of bridge. Center of capsill roller beam must be directly

over capsill roller beam peg.

(b)

Ensure capsill roller beam is at right angle (900) to centerline of bridge.

(c)

Lock rollers.

(8)

Operate jacks in capsill roller beam until weight of bridge is on capsill roller beam and off packing.

(9)

Remove packing.

(10) Position capsill beam at required height for delaunch. Use carpenter’s level to level roller beam.

(11) Move vehicle into position about 15ft (4.6m) from end of bridge. Ensure vehicle is in line with bridge and

centered over centerline.

(12) Connect vehicle to bridge with long push bar (para. 4-18c.).

NOTE

The bridge will be held in position by the vehicle and locked rollers of roller beam during

assembly of launching nose.

(13) Connect launching nose roller to far bank bankseat beam (para. 4-10).

(14) Assemble launching nose (para. 4-14a.).

(15) Using landing roller pedestal, raise far bank end of bridge until jack is fully extended.

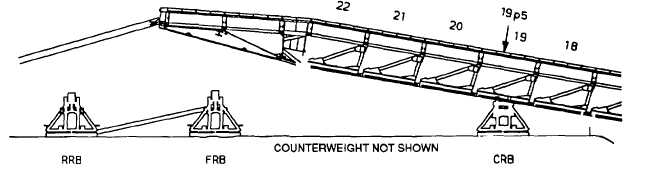

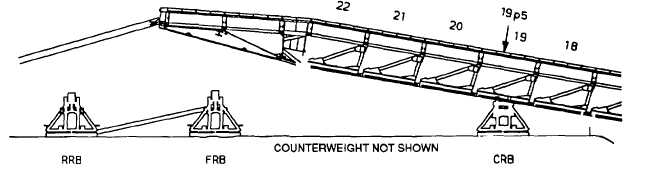

(16) Unlock rollers. Delaunch bridge until panel point 19p5 is over center of capsill roller beam. Do not

disconnect push bar.

(17) Assemble and position front roller beam (FRB) 30 ft (9.1 m) from capsill roller beam and rear roller beam

15 ft (4.6 m) from front roller beam. Ensure centers of roller beams are over centerline of bridge and

roller beams are at 900 to centerline. Position RRB using longitudinal girders, then disconnect girders

from RRB and place on the ground.

(18) Level roller beams.

(19)

Delaunch bridge to panel point 10p7 (over CRB).

6-51