TM 5-5420-228-24

HYDRAULIC PUMP REPAIR (Sheet 6 of 11)

CLEANING AND INSPECTION:

Compressed air used for cleaning purposes will not exceed 30 psi.

Use only with effective chip guarding and personal protective

equipment goggles/shield, gloves, etc.

Dry cleaning solvent PD-680 is toxic and flammable. To prevent

personal injury, wear protective goggles and gloves and use only in a

well-ventilated area. Avoid contact with skin, eyes, and clothes and

don't breathe vapors. Do not use near open flame or excessive heat.

The flash point for Type #1 Dry Cleaning Solvent is 100F (38C)

and for Type #2 is 138F (50C). If you become dizzy while using

cleaning solvent, get fresh air immediately and get medical aid. If

contact with eyes is made, wash your eyes with water and get

medical aid immediately.

1. Using rags and dry cleaning solvent, wash all metal parts arid dry with compressed air.

CAUTION

Do not spin bearings by hand. This causes wear on parts

when not lubricated.

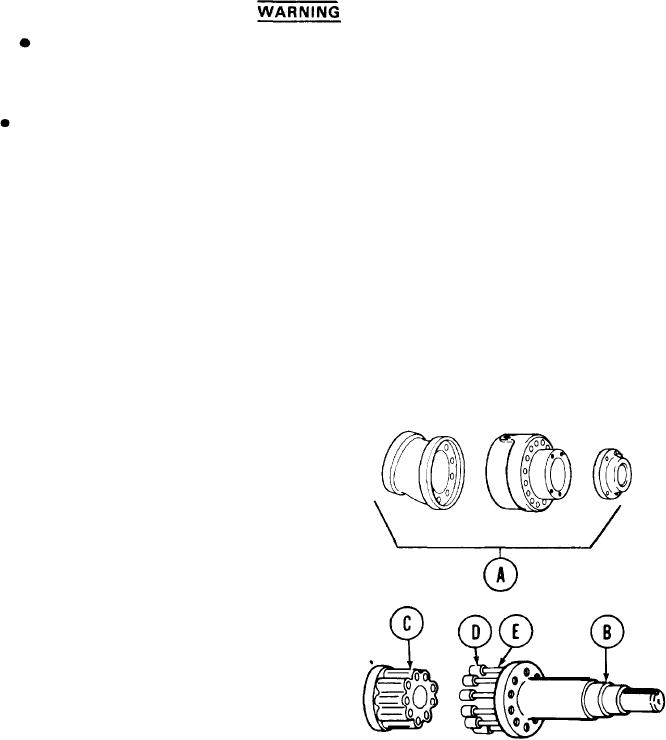

2. Check all inside and outside surfaces of pump

housing (A) for nicks, scratches, gouges,

warping, burrs, or dents. Small nicks, scratches,

and burrs may be removed with crocus cloth. If

other damage is found, replace housing (A).

3.

Check threads of all attaching parts for stripping

and wear. Replace as necessary.

Examine drive shaft (B), cylinder block

4.

(C), and each piston (D) for scratches

and nicks. Make sure each connecting

rod (E) turns freely at both ends. Test

cylinder block (C) sockets by installing

and removing each piston (D) in each

socket. Fit should be firm and smooth.

C h e c k outside of drive shaft (B) and

cylinder block (C) for burrs and nicks.

Using lapping compound, dress down all

R e p l a c e drive

tiny burrs and nicks.

shaft (B), cylinder block (C), or both, if

anything more than tiny burrs or nicks

are found.

Go on to Sheet 7

TA251697