ARMY TM 5-5420-212-10-1

MARINE CORPS TM 08676A-10/1-1

b.

The time for construction can be decreased through drill training and thorough planning of the mission.

c.

Poor site conditions, inclement weather, and unskilled personnel will increase construction time.

3-9

WORK PARTY REQUIRED

The work parties required for all MGB’s are given in Table 1-5. Decreasing the size of the work party will

considerably increase building times. Increasing the number of personnel will not necessarily decrease the building times.

Section IV. Design

MGB design is a two phase operation to determine the length of the bridge, type of construction, correct setting of

roller beams, setting of the launching nose cross girder, and determining the time, personnel, and bridge loads required.

3-10

DESIGN PHASE 1

In this phase, the preliminary studies, site selection and reconnaissance are performed to determine the bridge

length, type of construction, and the location and elevations of the key construction points on the site. This is the onsite

phase. Two parts of this phase are common to all bridge lengths (measuring the AR Gap and selecting the bridge).

a.

Measure the angle of repose (AR) Gap

(1)

Select a bridge centerline. The length of the centerline (on each bank) will be determined by the R

distance (construction space) required for the bridge that will be built. R Distances range from 5.8m to 40.5m (does not

include the length of the launch vehicle or the push bar). Initially a centerline should extend approximately 5.0m on each

bank. Once the AR Gap and the bridge length has been determined, the centerline will be extended to the correct R

Distance plus the length of the launch vehicle and the push bar. This will ensure that there is sufficient space on both

banks for vehicle access or egress, and space on the near bank for construction of the bridge. There should be sufficient

clear area extending out 3.0m on both sides of the centerline for its full length to allow for bridge construction. Additional

clearance on each side is required for pallet placement and off-loading.

(2)

Determine the location of firm ground on both the near and far banks.

(a)

For the field method of determining firm ground, assume the AR of the soil to be at 45 degrees.

The soil bearing capacity should be at least 2 tons per square foot. Capacities less than 2 tons will require placement of

timber packing under the bridge.

(b)

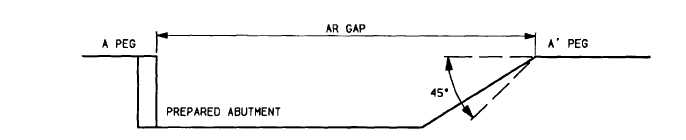

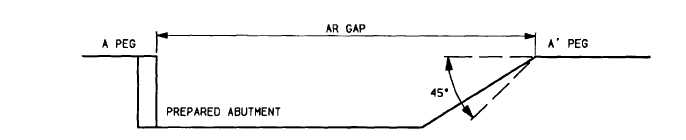

At the edge of firm ground on the near bank, place the A’ peg. At the edge of firm ground on the far

bank, place the A peg. The distance between the two pegs is known as the AR Gap. Keep in mind that the MGB must not

bear on the ground for more than 2.1m (for SS) or 2.3 m (for DS), regardless of its length.

1

If the actual slope of the bank does not exceed 45 degrees from the horizontal, place A and A’

pegs as shown in Figure 3-5

Figure 3-5. Angle of Repose with Slope of Bank Less than 45 degrees.

3-16