TM 5-5420-226-20-2

FUEL-WATER SEPARATOR OPERATIONAL TESTS (Sheet 11 of 11)

Sequential Drain Test (Sheet 4 of 4)

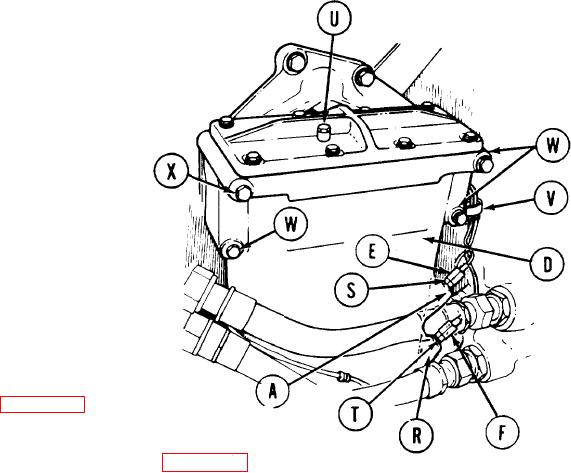

17. Using adjustable wrench, remove two pipe plugs from upper (A) and lower (R) sensor holes.

18. Using 1/2 inch wrench to hold sensor

retaining nut (S), use 9/16 inch wrench

and install upper sensor (E) into fuel-

water separator (D).

19.

Using 1/2 inch wrench to hold down sensor

retaining nut: (T), use 9/16 inch wrench

install lower sensor (F) into fuel-water

separator (D).

20. Using 7/16 inch socket, close bleed

cap (U) until snug by turning clock-

wise.

21. Position clamp (V) onto fuel-water

separator and, using 1/2 inch socket,

install three capscrews, lockwashers,

and flat washers (W).

22. Using 1/2 inch socket and extension,

tighten capscrew (X).

23. Install powerplant (page 5-14).

24. Perform fuel system bleeding procedure (page 7-64).

End of Task

TA107847

7-240