TM 5-5420-226-20-2

FUEL TANK REPAIR (Sheet 2 of 2)

WARNING

Use dry cleaning solvent in a well-ventilated area only.

CLEANING:

1.

Using dry cleaning solvent, clean area around crack to remove all traces of dirt and

grease. Wipe dry with rags.

2.

Using sandpaper, sand area around crack for proper adhesion of sealer. Wipe with rag

after sanding.

REPAIR:

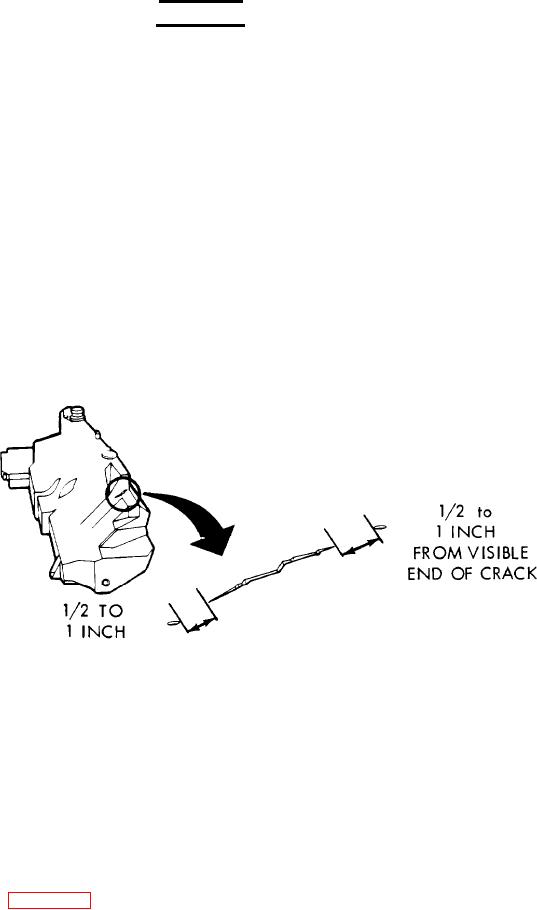

1.

Using ruler, mark spot to bore hole 1/2 to 1 inch from ends of crack on a line with crack.

Coat drill bit with grease to minimize amount of metal chips falling into fuel tank.

2.

3.

Using drill, bore hole about 1/2 to 1 inch from visible ends of crack as shown.

4.

Clean crack and surrounding area with rag dampened in dry cleaning solvent. Wipe dry.

Do not allow fingerprints, oil, or moisture on cleaned surface.

NOTE

Do not apply sealer at temperatures below 45 degrees F. Sealer will cure in

approximately 24 hours at room temperature.

5.

Mix accelerator and sealer in container.

6.

Apply 3/16 inch thickness of sealer to cleaned surface and at least 1/2 inch beyond crack.

7. Install powerplant (page 5-14).

TA169896

End of Task

7-371/(7-372 blank)