TM 5-5420-226-20-3

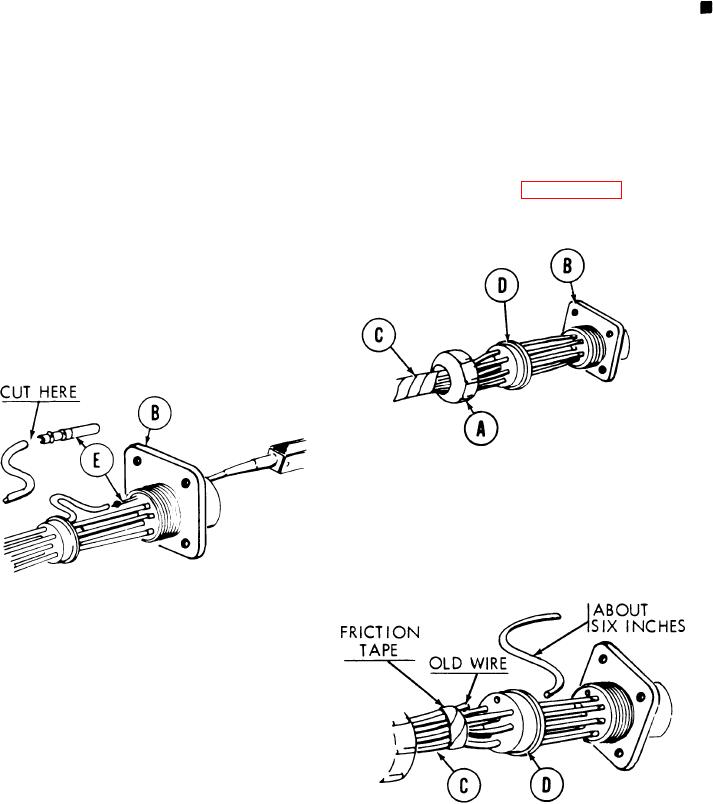

ELECTRICAL WIRING HARNESS AND CABLE CONNECTOR REPAIR (Sheet 16 of 18)

Female Receptacle Repair (Sheet 1 of 3)

Electrical connector repair tool kit

TOOLS:

Soldering gun

Slip joint pliers with plastic jaw inserts

Diagonal cutting pliers

Pocket knife

Heat gun

Silicone compound (Item 32, Appendix D)

SUPPLIES:

Heat-shrink tubing (Item 60, Appendix D)

Electrician's tape (Item 59, Appendix D)

Jumper wire

Disconnect three battery ground straps (page 10-268)

PRELIMINARY PROCEDURES:

Loosen or remove cable clamps as required

Disconnect connectors at each end of affected cable

Manually remove grommet retaining nut

1.

(A) from plug assembly (B).

Slide grommet retaining nut (A) back along

2.

cable (C).

3.

Using slip joint pliers, work grommet (D)

back and forth and out of plug assembly

(B).

4.

Using remover, push contact (E) with

damaged wire out of back of plug

assembly (B).

5.

Using diagonal cutting pliers, cut wire

from contact (E). Throw away contact (E).

Pulling cut wire out of grommet (D), use

6.

diagonal cutting pliers to shorten wire

about 6 inches. Fasten new end of cut wire

to cable (C) with friction tape.

Go on to Sheet 2

10-313