TM-5-5420-279-10

Section III. LUBRICATION AND FLUID LEVEL CHECKS

General

WARNING

TO ENSURE THE SAFETY OF PERSONNEL, ALL TOOLS AND EQUIPMENT MUST BE KEPT

CLEAN AND DRY TO PREVENT THE OPERATOR FROM SLIPPING AND CAUSING

PERSONAL INJURY.

Note

The DRY SUPPORT BRIDGE (DSB) Launch Frame is NOT enrolled in the Army Oil Analysis

Program.

Lubrication instructions for the PLS Vehicle, including the hydraulic fluid for the DSB

Launcher can be found in TM 9-2320-364-10.

8.7.1.1

The lubrication and hydraulic fluid requirements of the PLS vehicle can be found in

Launcher without bleeding the system.

8.7.1.2

These instructions only detail lubrication of the DSB Launcher A-frame, launch

frame, crane and tail-lift, not the hydraulic system which is covered in the PLS

manuals.

8.7.1.3

Keep all lubricants in sealed containers to prevent contamination from foreign

particles, e.g. dust or dirt. The containers must be stored in a clean dry place away

from external heat sources.

8.7.1.4

Lubrication tools and equipment shall be kept clean and ready for use at all times.

Lubrication Periods

8.7.2.1

Lubrication maintenance is based on hours run rather than launches and retrieves,

as the time to launch and retrieve is variable.

8.7.2.2

The time is obtained from the hours run counter on the operators interface panel.

8.7.2.3

The lubrication on the launcher, crane and tail-lift is to be carried out every 50 hours

unless otherwise stated in Table 8.5. This periodicity will take into account any

extreme conditions the launcher may encounter.

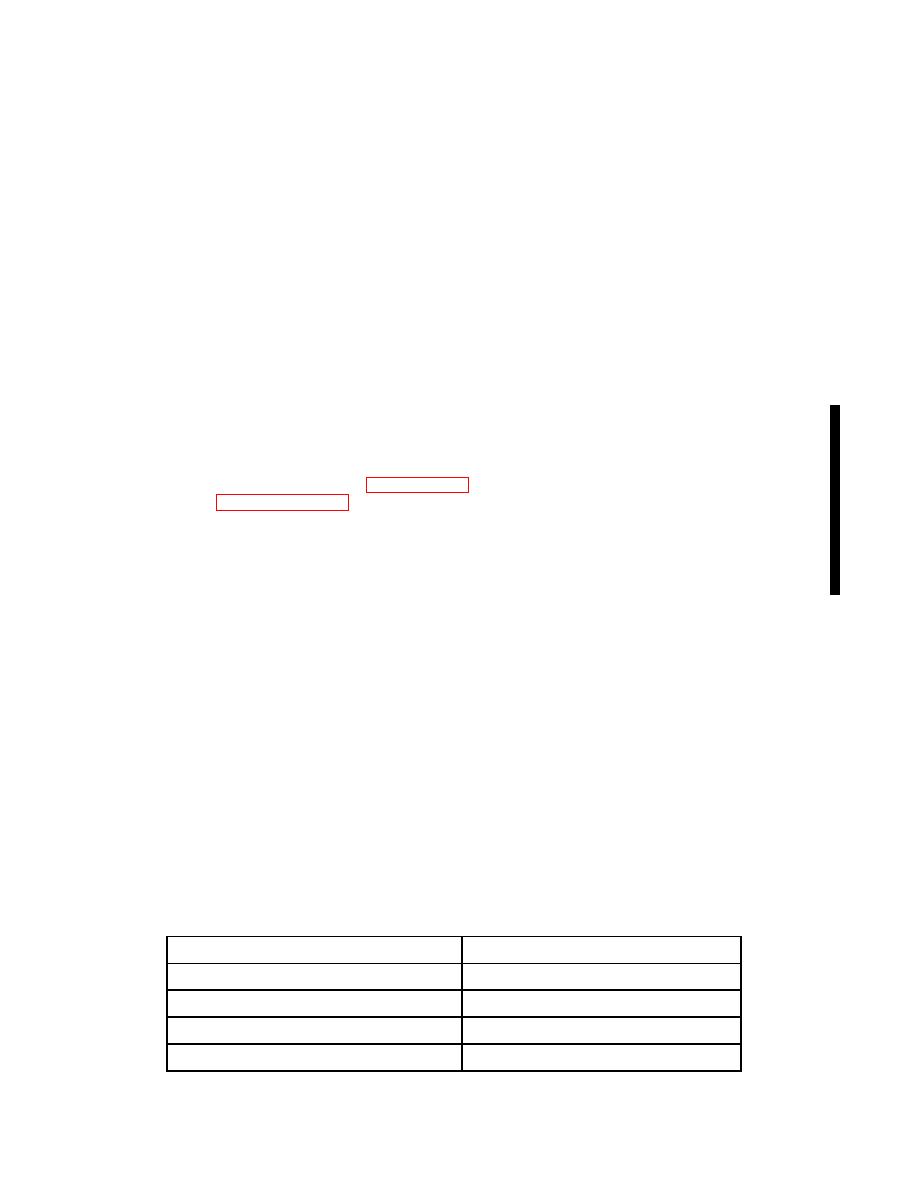

Table 8.5 Lubrication Periodicity

System

Period

A-frame

50 Hours

Launcher

50 Hours

Crane

50 Hours

Tail-lift

50 Hours