TM

5-5420-202-20-2

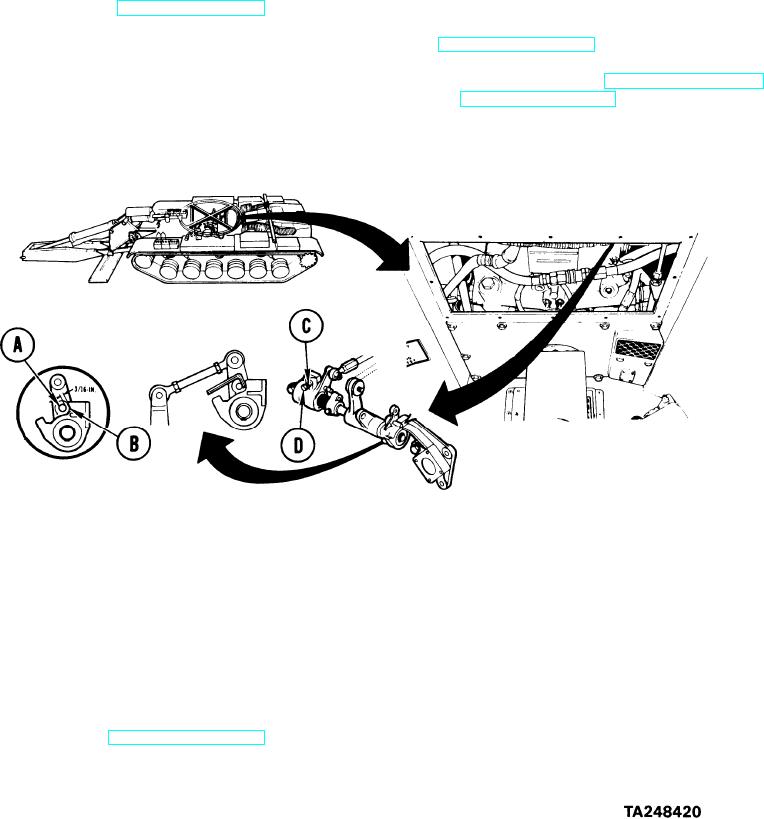

ENGINE IDLE ADJUSTMENT (Sheet 1 of 1)

TOOLS: 1/2 in. combination box and open end wrench

F l a t - t i p screwdriver

FABRICATED

TOOLS:

Throttle linkage adjusting go/no go gage

(Figure F-3, Appendix F)

REFERENCE:

P R E L I M I N A R Y PROCEDURES:

Engage parking brake (TM 5-5420-202-10)

Remove upper engine access cover (page 17-11)

Block tracks to prevent vehicle movement (TM 5-5420-202-10)

Start engine, run at idle (TM 5-5420-202-10)

ADJUSTMENT:

1.

Using 3/16 inch end of fabricated gage, measure distance between stop pin (A) and bracket

shoulder (B).

2.

If distance is more than or less than 3/16 inch, use wrench and loosen jamnut (C) on idle

adjustment screw (D).

3.

Using screwdriver, turn screw (D) to the right to increase distance, and to the left to decrease

distance.

4.

Using wrench, tighten jamnut (C).

5.

Check idle speed. If it is not between 700-750 rpm (shown on tachometer), notify support

maintenance.

6.

Stop engine (TM 5-5420-202-10).

7.

Install upper engine access cover (page 17-12).

End of Task