TM 5-5420-202-20-3

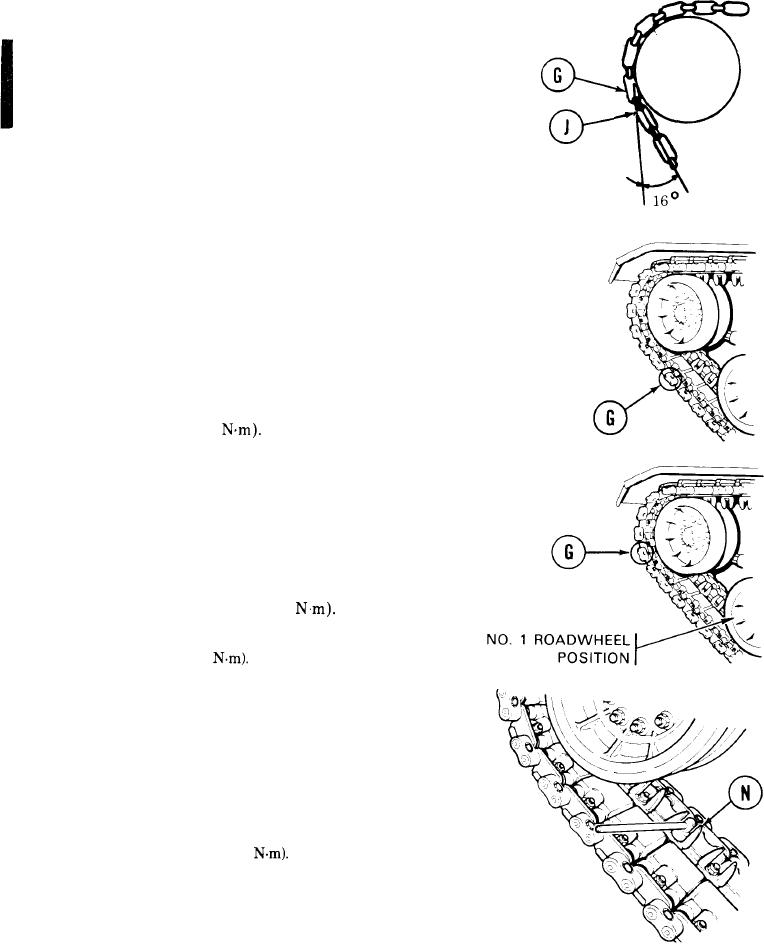

TRACK ASSEMBLY REPLACEMENT (Sheet 9.1 of 10)

NOTE

If track torquing tool kit is available,

go to step 49. If not available, go to

step 42.

42. Have other person start engine (TM 5-5420-202-

10. Slowly move vehicle until track link in

front of' end connector (G), just installed, is

fully engaged over the compensating idler

wheel and the track link, after end connector

(G) is just touching the compensating idler

wheel.

43. Using torque wrench with 15/16 inch socket,

tighten end connector wedge (J) bolts to

180-200 lb-ft (244-271

44. Move tank until end connector (G) is in lower

position.

45 Move tank until end connector (G) is located in

same position as step 42. Using torque wrench,

tighten to 180-200 lb-ft (244-271

46. Repeat steps 42 thru 44 until torque stays at

180-200 lb-ft (244-271

47. Move tank until centerguide (N) is between

compensating idler wheel and No. 1 roadwheel

position.

48. Using torque wrench, tighten centerguide nut

(F') to 350-380 lb-ft (474-515

Go on to Sheet 9.2