TM 5-5420-202-34

FINAL DRIVE REPAIR (Sheet 30 of 30)

5.

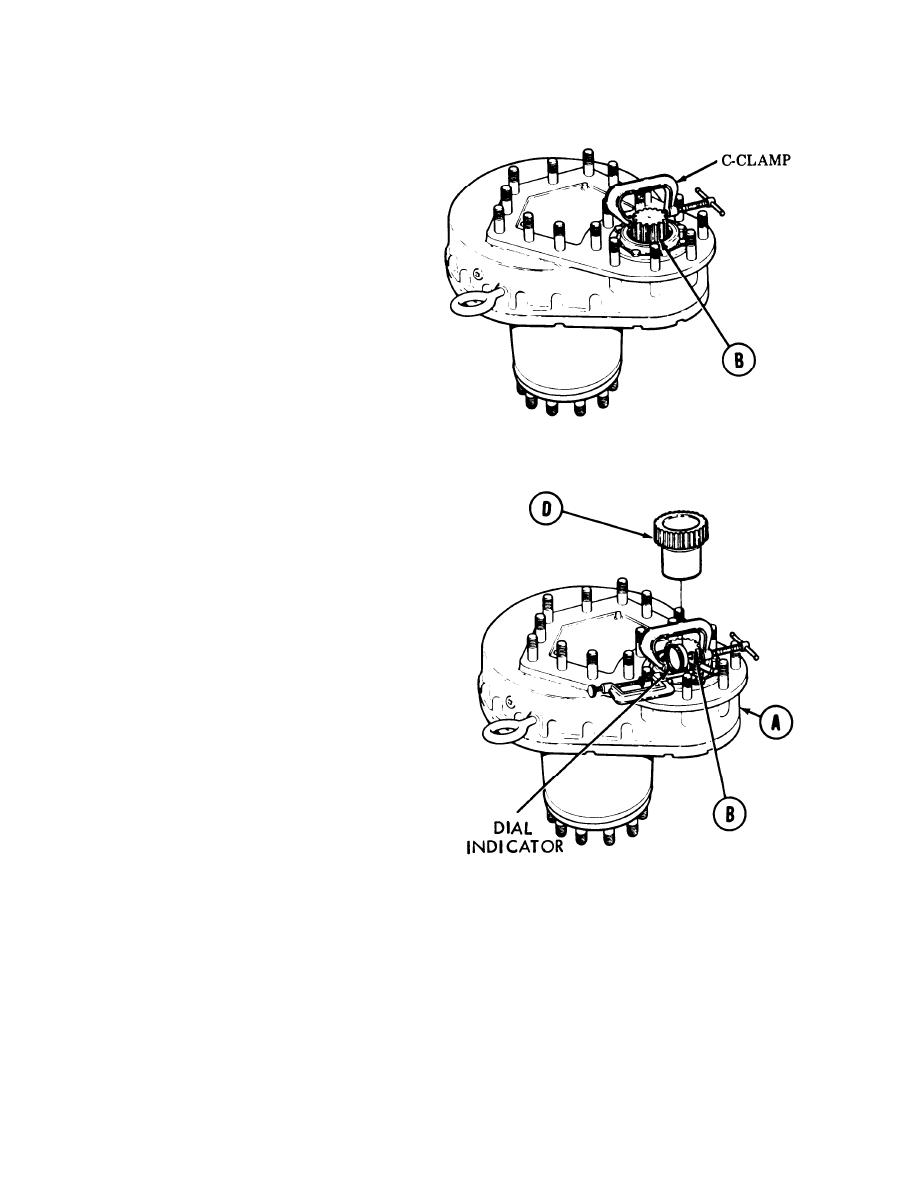

Using C-clamp, rotate pinion shaft

(B) counterclockwise until slight pressure

(drag) is felt.

NOTE

Ensure pinion splines are clean

and free of chips, burrs, oil, and

dirt before installing dial indi-

cator.

6.

Install dial indicator. Set dial indicator to

zero.

Rotate pinion shaft (B) clockwise until

7.

slight pressure (drag) is felt.

8.

Record dial indicator reading.

9.

Remove dial indicator. Rotate pinion

shaft (B) one complete revolution.

10.

Repeat steps 5 thru 9 three times.

11.

If all four readings are between 0.006 and

0.032 inches, remove C-clamp and install

adapter (D). Package final drive (A) for

shipment and return to supply. If readings

are not within tolerance, go to step 12.

Replace pinion gear and drive gear (matched set) (Disassembly steps 1

12.

thru 29) (Assembly steps 54 thru 86). If replacement gears are not

within tolerance, tag final drive (A) "UNSERVICEABLE (BACKLASH)"

and return to supply for depot rebuild.

End of Task

7-30 Change 2