TM 5-5420-226-20-3

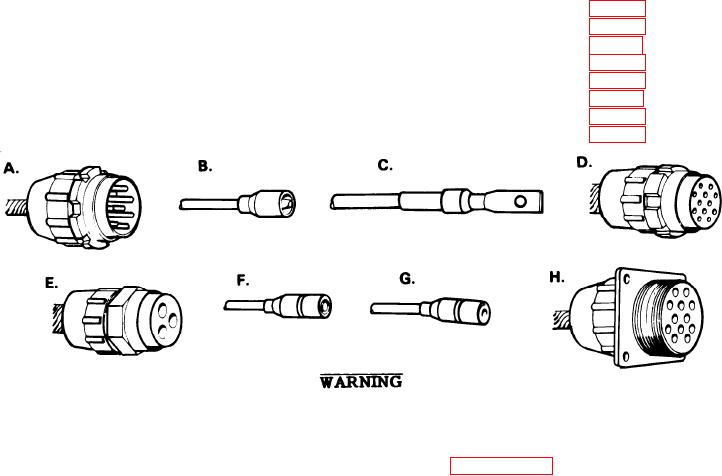

ELECTRICAL WIRING HARNESS AND CABLE CONNECTOR REPAIR (Sheet 1 of 18)

PAGE

PROCEDURE INDEX

A.

Male Plug Repair

B.

Male Connector Repair

Terminal Connector Repair

C.

D.

Female Plug Repair

E.

Female Plug Repair

Female Connector With Washer (12 Gage Cable) Repair

F.

Female Connector With Sleeve (14 and 16 Gage Cable) Repair

G.

H.

Female Receptacle Repair

Some wiring harness and cables are hot even if MASTER

BATTERY switch is set to OFF. Make sure the three

disconnected before

battery ground cable assemblies are

disconnecting any wiring harness or cable (page 10-268).

NOTE

When replacing a bad pin or contact, the opposite pin or

contact at the other end of the cable must also be replaced.

Do not disassemble the harness. Use a jumper wire of the

same gage wire being replaced, cut to the length of the

affected cable. When repairs to both connectors com-

plete, tape the jumper wire to the outside of the cable with

friction tape. The jumper wire should be taped at least

every 6 to 8 inches, but in no case should any part of the

wire be allowed to hang loose.

NOTE

After a plug, receptacle, or connector in the engine com-

partment has been repaired and the cable or jumper wire has

been installed brush or spray the cable or jumper wire with

electrical insulating compound. allow the compound to dry

for about 24 hours before handling. the compound is an

insulator of electricity, so care must be to to keep from

overspraying the compound on contacting surfaces of wire

terminals, connector pins or contacts, or similar parts where

it will prevent the flow of electricity.

Go on to Sheet 2

Change 1