TM 5-5420-226-20-2

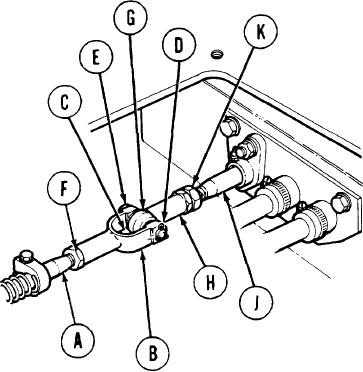

ACCELERATOR LINKAGE ADJUSTMENT (Sheet 2 of 6)

ADJUSTMENT:

Check to see that threaded shaft (A) is flush with

1.

inside of clevis (B) at location (C). If threaded

shaft is flush, go to step 5. If threaded shaft is

not flush, go to steps 2, 3, and 4.

Using pliers, remove cotter pin (D) and pin (E).

2.

Throw cotter pin away.

Using 9/16 inch wrench to hold clevis (B), use

3.

1/2 inch wrench to loosen nut (F) and adjust

clevis (B) so that shaft is flush with clevis.

Using 9/16 inch wrench to hold clevis (B), use

4.

1/2 inch wrench to tighten nut (F).

Insert 1/16 inch diameter pin at location (G)

5.

in rod end bearing (H) to be sure that threads

of tube assembly (J) go into rod end bearing

beyond location (G). If tube assembly is not

inserted beyond locatin (G), go to steps 6 and

7. If tube assembly is inserted beyond location

(G), go to step 8.

Using 7/16 inch wrench to hold rod end bearing (H)

6.

(on flats) and 1/2 inch wrench to loosen nut (K),

adjust rod end bearing as stated in step 5.

Using 7/16 inch wrench to hold rod end bearing (H)

7.

(on flats), use 1/2 inch wrench to tighten nut (K).

NOTE

Rod (H) or clevis (B) may be

pulled in order to insert pin (E).

8.

Insert pin (E) and, using pliers, install new cotter

pin (D).

TA108045

Go on to Sheet 3

7-339