TM-5-5420-279-10

NOTE

Flatracks T1 and V3 are modified with a wooden spacer fitted to prevent the ramp jaws

damaging the flatrack storage box. The wooden spacer is fitted to the flatrack when a

ramp module is stored on top of another bridge module.

5.4.7.36

Make sure the far bank ramp module closes slowly and progressively as it is lifted by

the crane. Do not operate the traverse controls of the crane until the module has

fully closed.

5.4.7.37

Ensure that the ramp module is correctly located over the transport aids fitted to the

parallel module.

686A659b

686A586a

686A659a

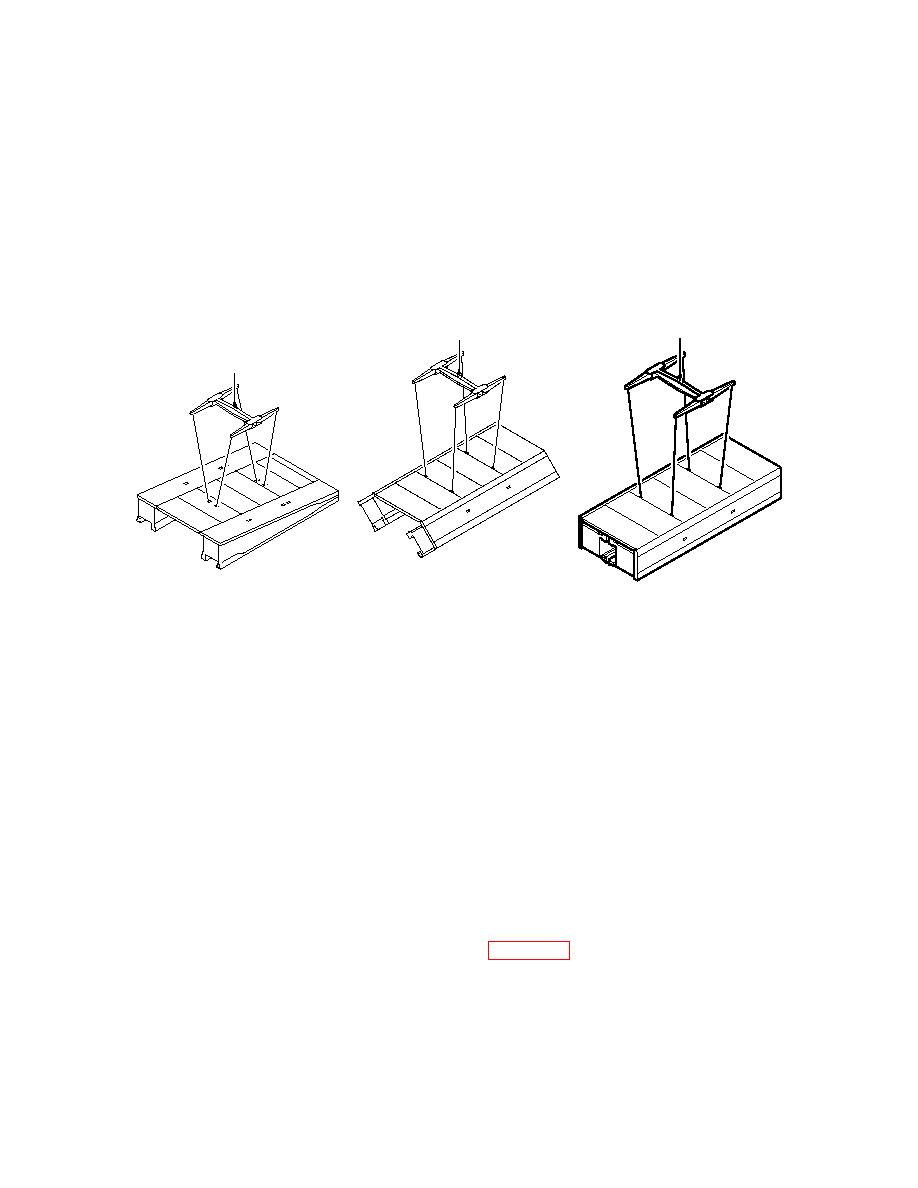

Sequence of Closing Ramp Module

5.4.7.38

Disconnect the bridge module lifter and the tag lines from the far bank ramp module.

5.4.7.39

Operate the lift and traverse controls on the crane, and position the bridge module

lifter over flatrack LVT.

5.4.7.40

Close the arms on bridge module lifter to the stowed position, and lower onto flatrack

LVT for stowing.

5.4.7.41

Disconnect the bridge module lifter from the crane hook.

5.4.7.42

Secure the bridge module lifter to the flatrack LVT with ratchet lashings.

5.4.7.43

Stow the single leg sling in the basket on LVT.

5.4.7.44

Operate the lift and traverse controls on the crane and position the crane hook at the

home bank end beam positioned on the ground.

5.4.7.45

Sling the home bank end beam, Refer to Figure 5. 3.

5.4.7.46

Connect the crane hook to the end beam slings and attach tag lines to the home

bank end beam positioned on the ground.

5.4.7.47

Place two bridging timbers on to flatrack T1 ready to receive the far bank end beam.

5-34